Production & Outsourcing

International Manufacturing & Outsourcing at JVK – Your Extended Workbench for Plastics Technology, Prototyping, and 3D Printing

Introduction: Outsourcing Reimagined – JVK as a Strategic Manufacturing Partner

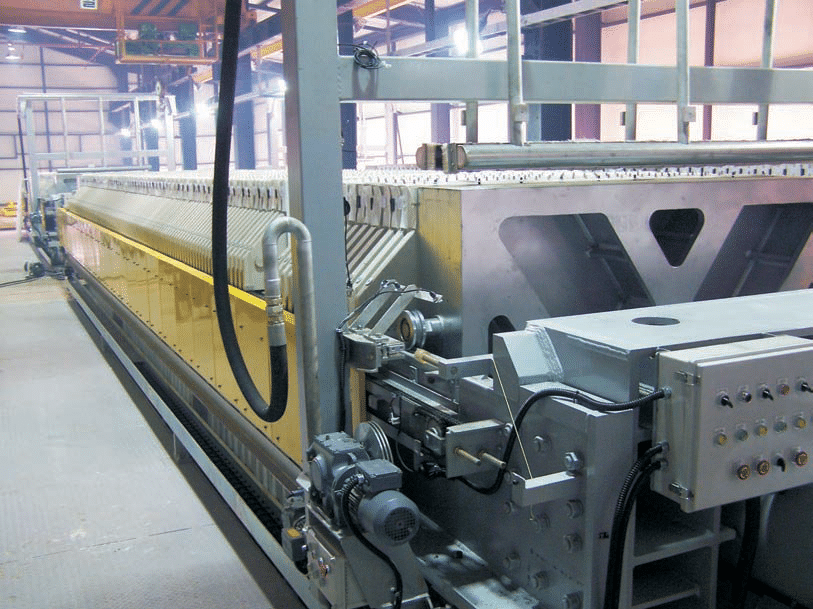

In a globalized world where flexibility, scalability, and quality determine economic success, strategic manufacturing partnerships are gaining increasing importance. JVK Filtration Systems positions itself as an internationally experienced outsourcing partner and extended workbench – especially in the areas of plastics engineering, casting, 3D printing, prototyping, and CNC machining.

Our Commitment: Tailored manufacturing expertise for your series or individual parts, precisely to specification, applicable across industries – extending far beyond our core competence in filter technology.

Area of Expertise 1: Additive Manufacturing (3D Printing) on an Industrial Scale

Today, 3D printing is a key area of modern product development and small-batch production. JVK offers high-resolution industrial 3D printing based on polymers – ideal for:

- Prototype Development

- Functional Parts for Small-Batch Production

- Geometrically Complex Components

- Integrated Assemblies with Snap-Fit, Sealing Lips, or Threads

Applications include:

- FDM Printing for Robust Geometries and Simple Iterations

- SLA/DLP for Smooth Surfaces and Complex Details

- SLS for Technical Components with Increased Mechanical Requirements

Our material range extends from standard PLA and PETG to technical plastics (e.g., PA12, ASA, TPU) and high-performance polymers. We also offer post-processing (e.g., grinding, painting, galvanizing).

Area of Expertise 2: CNC Machining & Precision Plastic Parts

JVK operates a modern CNC department for high-precision machining of technical plastics. Our machine park includes 3- and 5-axis machining centers, automated clamping systems, and CAM interfaces for direct data transfer from CAD systems. We manufacture:

- Plate Cores and Mold Inserts

- Support Structures and Adapter Elements

- Fixtures for Mechanical Engineering

- Sample Parts for Test Benches or Pre-Series

Available materials: PE, PP, PVDF, POM, PA, PC, PTFE, technical compounds, ESD-safe materials – each with documented material batch tracking. Thanks to our many years of specialization in chemically demanding and hygienically critical application areas, we know what matters when it comes to dimensional accuracy, sealing surfaces, and media compatibility.

Area of Expertise 3: Casting Processes & Molded Part Development

For decades, JVK has been manufacturing complex plastic parts using casting processes – whether for our own filter plate production or as a contract manufacturer for external partners. Our molds are designed in-house, manufactured using CAM, and realized from aluminum or steel according to customer requirements.

We cast:

- technical PP and PVDF components

- Special Materials with Plasticizer or Conductivity Components

- Large-Surface Parts with Mold Inserts or Cores

- Rubber and Membrane Composite Parts in Hybrid Technology

Complex mold transitions, multi-component parts, and detachable separation systems are also feasible. Small series or series production with demanding repeatability – our casting department delivers reliable results.

Area of Expertise 4: Prototyping & Rapid Iteration

Especially in product development, speed and functional validation are crucial. JVK offers a structured prototyping workflow – from idea to tested component:

- Design Support and CAD Optimization

- 3D Printing in Production Materials

- Functional and Fit Prototypes

- Leakage and Media Compatibility Tests

This way, you reduce iteration loops and minimize your development risk – with high speed and predictable costs.

Diverse Industries – Applications Far Beyond Filter Technology

Our outsourcing customers come from a wide range of industries:

- Mechanical Engineering & Special Machine Construction

- Environmental Technology & Water Treatment

- Energy Supply & Power Plant Technology

- Medical Technology & Biopharma

- Research Institutions & Universities

Typical orders include prototype parts, sealing components, brackets, media-carrying plastic bodies, small series for pilot plants, or special parts for complex apparatuses. With JVK, you gain technical understanding, manufacturing experience, and partnership-based communication at eye level – in every project phase.

JVK as an Outsourcing Partner – Your Advantages at a Glance

- Extensive Manufacturing Depth: CAD, CAM, CNC, 3D Printing, Casting, Rubber, Mold Making from a Single Source

- Technical Engineering & Development Expertise

- Fast Response Time & Small-Batch Production Capability

- Material Variety & Media Expertise (Chemistry, Pharma, Food, ATEX, FDA)

- Proven Supply Chain for International Customers

- Absolute Confidentiality & Protection of Intellectual Property

- Documentation, CE/FDA Conformity upon Request

Conclusion: Trust JVK as an Extended Workbench for Your Development and Production

Whether as temporary development support, an external prototyping partner, or a permanent manufacturing service provider – JVK supports you with expertise, machine capacity, and an engineering mindset. Together, we develop and manufacture what is technically sound, economically feasible, and functionally convincing.

Inquiries

Contact us for your outsourcing inquiry. We would also be pleased to advise you personally on cooperation models, pilot projects, or production transfers.

jvk@jvk.de or by phone at +49 (0) 9172 707 0.

Additional Services

Consulting & Product Development

Design & Planning

Production & Outsourcing

Maintenance & Care