Maintenance & Care

Maintenance & Care of Filter Plates – Why JVK's Services Secure Your Production

Introduction: Maintenance as the Key to Production Reliability

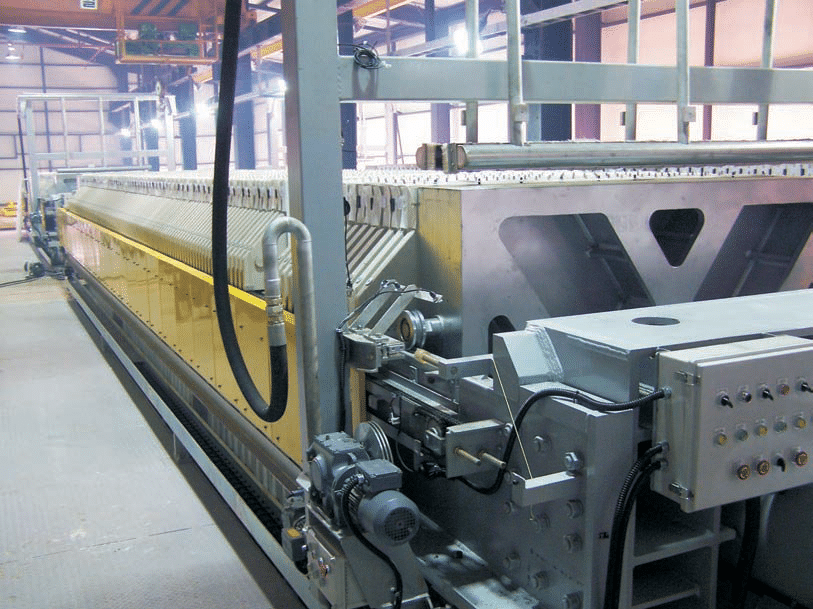

Filter plates are the core of every chamber filter press – and at the same time, highly stressed components in daily operation. Pressure, temperature, aggressive media, and mechanical stress lead to material fatigue, seal wear, and structural changes in the long term. Regular maintenance and care of these critical components is therefore not an option, but an essential part of production planning. JVK offers a comprehensive maintenance system for filter plates, membrane plates, and filter cloths – tailored to systems of all sizes and manufacturers. Our goal: maximum operational reliability, minimal downtime, and extending the service life of your system.

Technical Basics: How and Why Filter Plates Wear

The service life of a filter plate depends on many factors:

- Number and pressure intensity of filtration cycles

- Temperature of the medium

- Abrasive properties (e.g., quartz content, sludge crystals)

- Chemical load (e.g., alkalis, acids, solvents)

- Cleaning methods (e.g., steam, high pressure, chemical cleaning)

Over time, micro-cracks, deformations, material hardening, hairline cracks in membranes, or leaching can occur. Sealing areas can also erode or warp, leading to leakage. Regular visual inspections, dimensional checks, and function tests are therefore essential – and part of every JVK service assignment.

Maintenance Packages from JVK – Tailored to Your Industry and Requirements

JVK offers flexible maintenance models:

- Basic check: visual inspection, measurement, cleaning, documentation

- Functional analysis: pressure load tests, deformation measurement, leak test

- Full maintenance: disassembly, cleaning, inspection, replacement of wear parts

- Cloth replacement service: cloth mounting inspection, new installation, tension control

The maintenance intervals depend on the industry and operating conditions:

- Food: frequent cycles, hygienic requirements

- Chemicals: chemically aggressive media, high material stress

- Mining: abrasive media, large plate formats

- Pharmaceuticals: FDA compliance, documented test cycles

All measures are completed with photo documentation, checklists, and maintenance recommendations.

JVK Advantage: Manufacturer-Independent Service

Regardless of whether your filter plates are from JVK or another manufacturer – our service technicians are familiar with the common plate types, materials, and sealing systems on the market. We have our own spare parts warehouses, CAD databases, and manufacturing capacities for the reproduction or adaptation of older series. Thanks to our experience with plastic molded parts, membrane assembly, and CNC milling centers, even complex repairs or conversions can be carried out.

Service Life Optimization Through Early Analysis and Care

Regular maintenance can achieve the following effects:

- Extension of plate service life by up to 40%

- Prevention of unplanned downtimes

- Reduction of energy losses due to leaks

- More uniform cake discharge

- Reduced consumption of filter cloths and sealants

JVK recommends an inspection cycle of 6 to 12 months, especially for cyclically loaded membrane plates. Our documentation can also be integrated into your QM systems (e.g., ISO 9001, GMP, HACCP).

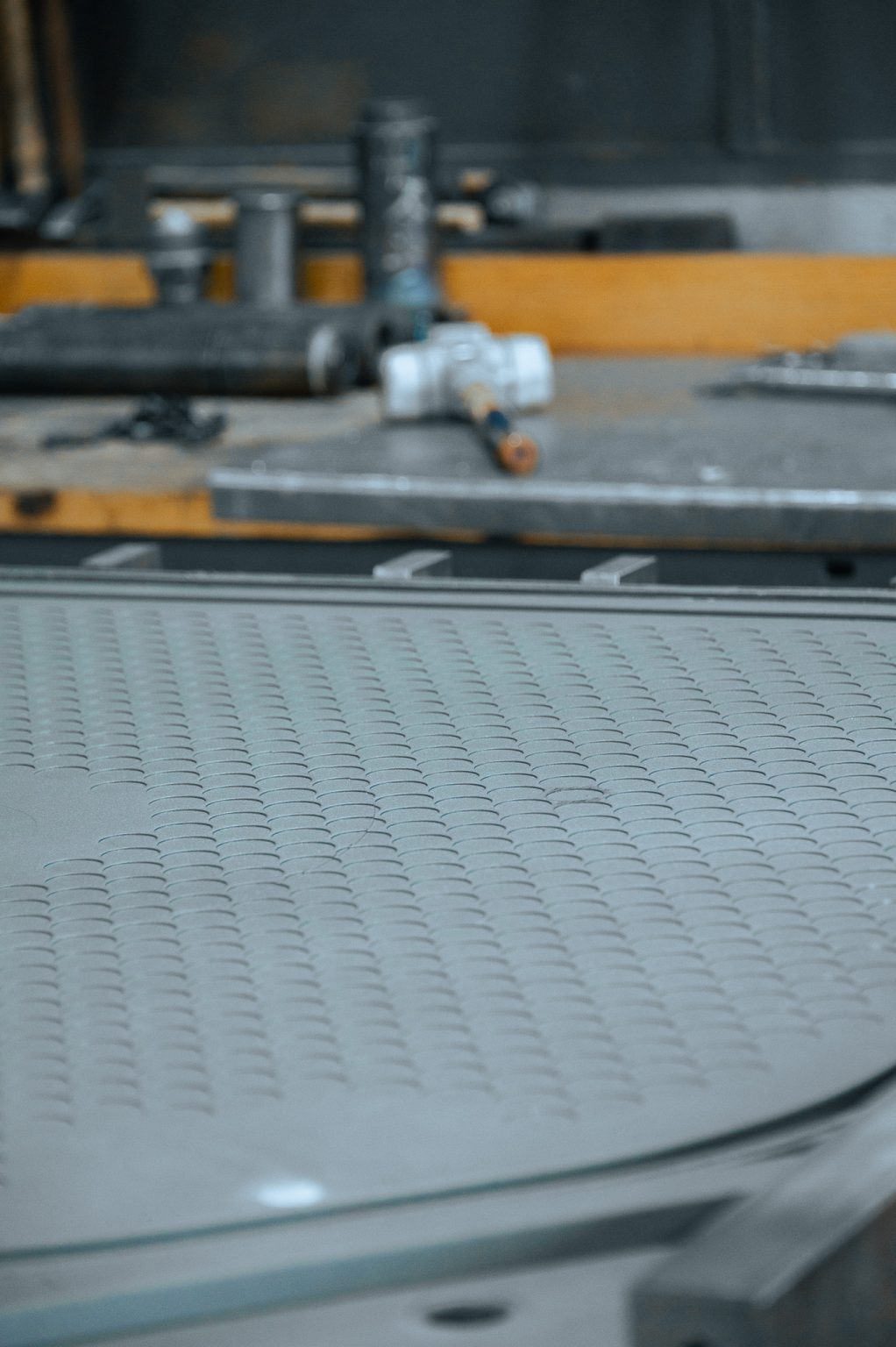

Material Knowledge as a Success Factor for Maintenance and Repair

The choice of the right material is crucial for the maintenance strategy. JVK exclusively processes high-quality, industry-proven materials – including polypropylene (PP), polyvinylidene fluoride (PVDF), high-density polyethylene (PE-HD), thermoplastic elastomers (TPE), and various rubber membranes.

Different maintenance and testing requirements exist for each type of material:

- PVDF plates: sensitive to selective mechanical stress, but highly chemically resistant

- PP membranes: must be regularly checked for softness and elasticity

- Elastomers: age under UV and ozone exposure – visual inspection for brittleness recommended

Our material experts can create individual maintenance manuals on request, tailored to your materials and processes.

Membrane Filter Plates: Maintenance at a Higher Level

Membrane filter plates enable a significant reduction in residual moisture in the filter cake through targeted post-compression. However, they also place higher demands on maintenance and control. The membrane itself is a highly stressed, often multi-layered component – consisting of carrier plates, anchoring elements, the actual membrane material, and sealing systems.

Maintenance Focus Areas for Membrane Plates:

- Checking the membrane tension and elasticity

- Testing for delamination or tears

- Checking the pressure chambers and pressing systems

- Replacement of membrane halves or complete plate combination

JVK® offers special testing and replacement tools that can be used to carry out safe filter membrane maintenance on site – without long downtimes.

Spare Parts Supply & Replacement Plates in OEM Quality

If the condition of individual filter plates makes a repair uneconomical, JVK offers fast replacement procurement – even for old or no longer available third-party products.

Our services:

- Reproduction of filter plates according to sample, drawing or scan

- Returning broken or worn filter plates for recycling

- Supply of OEM-compatible filter plates, filter membranes and seals

- Complete set delivery for planned filter panel replacement

Thanks to our in-house mold construction, our CNC technology, and a CAD database with over 1000 filter plate variants, we are able to provide highly compatible replacement solutions even at short notice.

Inquiries

Have your filter plates professionally inspected, maintained, and digitally recorded – together with an experienced partner.

jvk@jvk.de or by telephone on +49 (0) 9172 707 0.

Additional Services

Consulting & Product Development

Design & Planning

Production & Outsourcing

Maintenance & Care