Consulting & Product Development

Holistic Service for Filter Plates & Filter Presses – From Concept to Maintenance

Research, Simulation, and Laboratory Tests

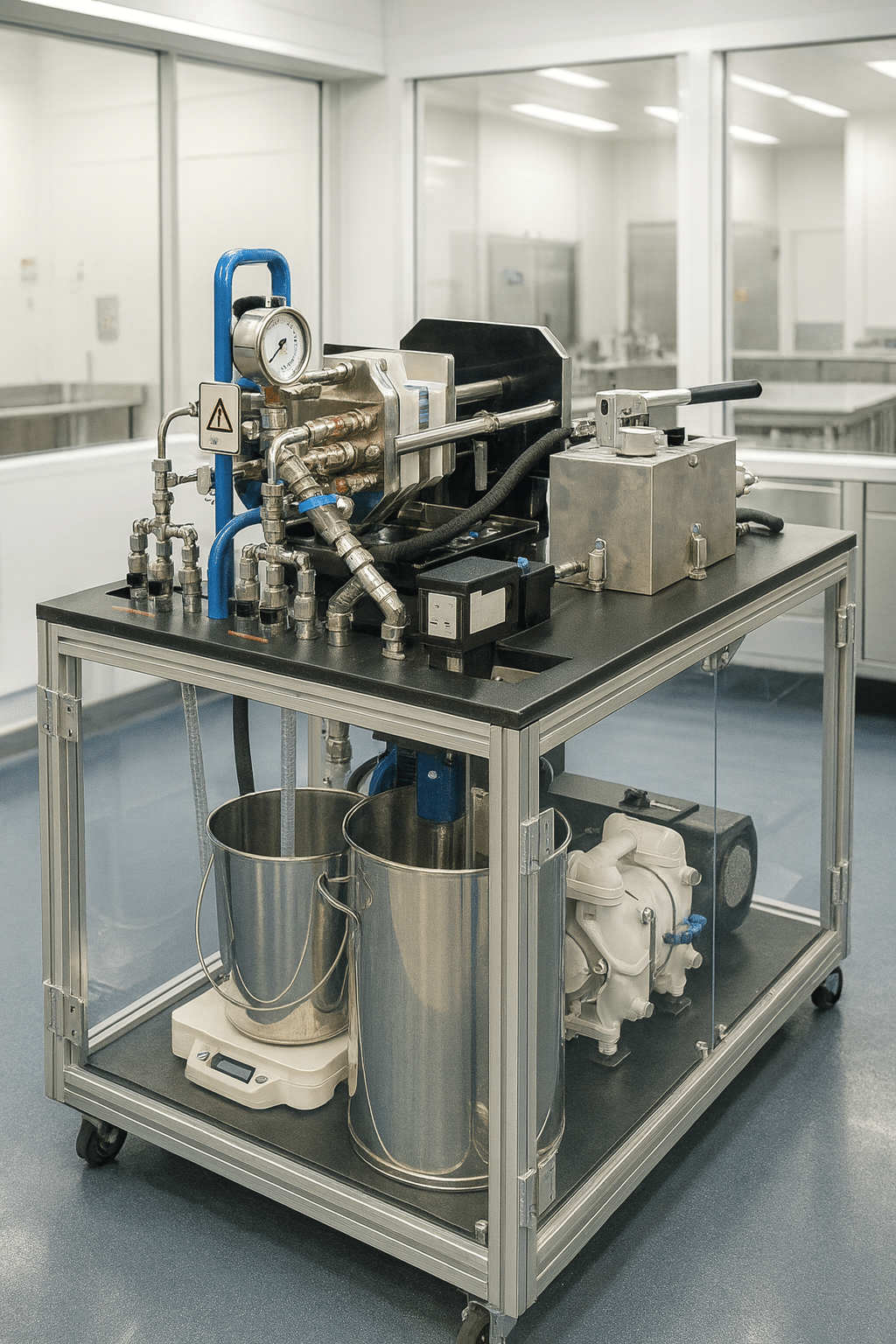

Before a new product goes into series production, we validate the design, material selection, and functionality under near-real conditions. Our laboratory filter presses, test benches, and FEM-supported simulations enable well-founded decisions – for example, regarding cake formation, filtrate quality, or mechanical load capacity. This ensures you receive a product that not only works in theory but also proves itself in practice.

Planning, Design, and CNC Manufacturing

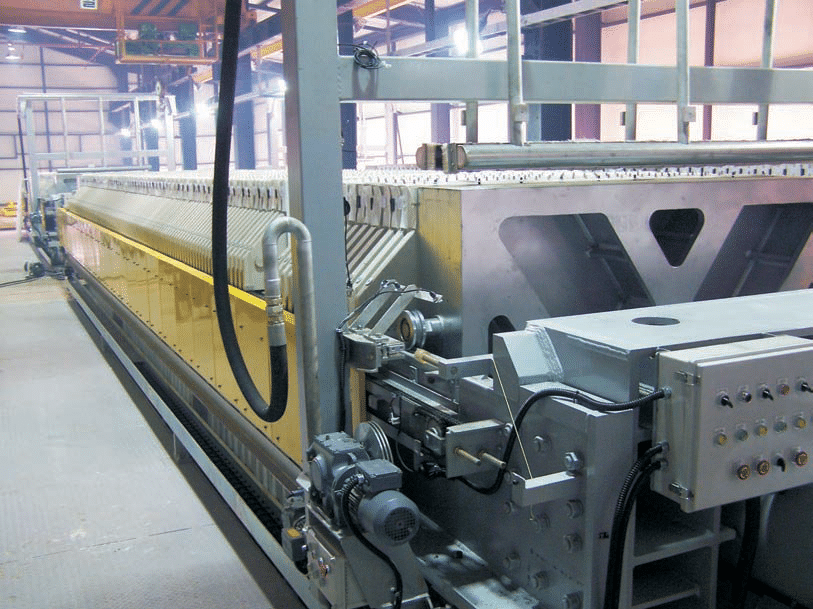

JVK® designs all filter plates and accessories on a CAD basis with the highest precision requirements. Our in-house mold shop manufactures molds, plate cores, tools and special components in controlled processes. This allows us to respond flexibly to special requests – from prototypes to small series. Our design services also include complete press systems or retrofit concepts for existing systems.

Production, Testing, and Quality Control

- Spare parts supply for filter plates, seals, membrane inserts

- Maintenance plans and on-site checks of your filter press

- Exchange and retrofit services for older plate systems

- Training of your personnel for handling and cleaning

- Long-term support for optimizations or expansions of your filtration processes

Further Comprehensive Development Services

In addition to our core competence in filter plate technology and membrane technology, we also offer comprehensive development services in the field of technical plastics processing. Thanks to our own CNC milling centers and modern 3D printing technology, we realize precise plastic components, special solutions, and functional prototypes. Whether media-carrying components, seal carriers, adapter elements, or complex functional geometries – we develop, design, and manufacture plastic parts exactly according to your specifications or accompany you in the new development from the ground up. We are also your reliable partner for small series or functional feasibility studies.

Conclusion: A Partner for All Phases of Your Project

Whether new development, process optimization, or technical modernization: JVK is your partner for holistic filtration solutions. We do not just deliver products – we deliver security, precision, and many years of experience.

Inquiries

Contact us for a personal consultation or request a customized offer.

jvk@jvk.de or by phone at +49 (0)9862 709-0.

Additional Services

Consulting and product development

Design and planning

Design & planning at JVK® – Technical excellence for customized filtration solutions

Production and outsourcing

International manufacturing and outsourcing at JVK® – your extended workbench for plastics technology, prototyping and 3D printing

Maintenance and care

Maintenance & care of filter plates – Why JVK® services safeguard your production

Introduction: The Significance of the Laboratory Filter Press in Research and Industry

In an era of rapid technological development and increasing demands on quality, sustainability, and process reliability, precise filtration solutions are of central importance for research institutions, universities, and industrial development departments. Laboratory filter presses (LFP) make it possible to simulate filtration processes on a small scale under realistic conditions and to optimize process parameters for production plants. With its decades of experience and technical innovation, JVK Filtration Systems has established itself as a reliable partner for laboratory systems – with a special focus on quality, modularity, and precision made in Germany.

Contents

- Technical Principles and Functionality

- Product Variants and Configuration Options

- Materials and Design Features

- Manufacturing Process at JVK – From Idea to Product

- Typical Applications in Research & Industry

- Practical Examples from Chemistry, Pharma, Food, and Universities

- Technological Innovations in Laboratory Filtration

- Advantages over Conventional Laboratory Systems

- Maintenance, Lifespan, and Spare Parts Supply

- Outlook: Automation, Digitalization, and Future Trends

- Conclusion: JVK Laboratory Filter Presses – Innovation Meets Practice

Technical Principles and Functionality

Laboratory filter presses operate on the principle of solid-liquid separation by means of pressure filtration. A medium to be filtered – consisting of liquid and solids – is pressed between several filter plates. These plates are covered with filter cloths that allow the liquid to pass through, while the solids remain on the surface. The result is a so-called filter cake, which is later evaluated, weighed, or further processed.

The advantages of this process lie in its scalability and precision: results from laboratory tests can be readily transferred to larger production facilities. This allows development departments to save not only time but also significant costs in the scale-up phase of new products.

Typical Operating Parameters of Laboratory Filter Presses:

- Number of plates: 1–12 filter plates (depending on configuration)

- Plate formats: 200 x 200 mm, 400 x 400 mm, among others

- Operating pressure: 6 – 15 bar

- Materials: Polypropylene, PVDF, stainless steel, special plastics

- Membrane options for active post-pressing

Product Variants and Configuration Options

JVK’s laboratory filter press features a modular design and is available in various versions. Depending on requirements, customers can choose between simple, manually operated systems and fully automated models with digital controls.

Main Variants at a Glance:

- Manual Laboratory Filter Presses: Ideal for research institutions with changing media. Compact, cost-efficient, easy to clean.

- Semi-automatic Variants: For recurring test series with higher reproducibility. Hydraulic closing systems, pressure monitoring included.

- Fully Automatic Laboratory Presses: For industry and R&D centers. Integrated sensor technology, touch displays, automatic post-pressing cycles.

Additionally, JVK offers individual configurations such as variable plate sizes, special membrane designs, or media-resistant housing materials. Ex-zone versions (ATEX) for use with flammable media are also available.

Materials and Design Features

JVK places the highest value on the material quality of its laboratory filter presses. All installed components comply with common standards for research, GMP, cleanroom, or industrial environments.

Available Materials:

- Polypropylene (PP): Standard material for laboratory plates. Lightweight, chemically resistant, easy to clean.

- PVDF: For aggressive media, high temperatures, laboratories with solvent or acid contact.

- Stainless Steel (1.4571 / 316Ti): For load-bearing components, frames, or contact surfaces with particularly high requirements.

- PTFE or special plastics: Optional for extreme media or special requirements (e.g., biolabs, ATEX).

The press design ensures that all components are easily detachable and accessible. The plates can be equipped with various filter cloths, membranes, or special coatings. Optionally available are sight glasses, sampling points, or automated sensor systems for pressure, temperature, and conductivity.

Manufacturing Process at JVK – From Idea to Product

- Needs analysis and consulting: Joint determination of process requirements with the customer (e.g., media, filtrate quantity, temperature, pressure).

- Design: CAD-supported development and simulation. Consideration of standards according to DIN, ISO, GMP, or customer-specific standards.

- Manufacturing: Precision machining of plates, housings, and components in CNC centers. Use of tested materials with traceability.

- Assembly and Testing: Each press is tested under real conditions (pressure test, leak test, functional test).

- Documentation and Training: CE Declaration of Conformity, operating manual, on-site instruction or video training upon request.

This high quality standard ensures JVK not only a long product lifespan but also a strong international reputation – especially in scientific and industrial research environments.

Typical Applications in Research & Industry

- Chemical Research: Analysis and filtration of reaction mixtures, catalyst recovery, pigment filtration

- Pharmaceutical Development: Clarification of extracts, filtration of active ingredients, validation of filtration processes

- Food Technology: Test samples of fruit juices, gelatin, plant extracts

- Environmental and Wastewater Analysis: Sludge investigations, landfill liquids, residue analyses

- Materials Research: Nanoparticles, ceramic suspensions, catalyst powders

Research laboratories and R&D departments particularly appreciate the ability to investigate a wide variety of media in experiments and simulate real scale-up scenarios with a single platform – yielding reproducible results and documented process parameters.

Practical Examples from Chemistry, Pharma, Food, and Universities

- University of Vienna – Faculty of Technical Chemistry: Used in the processing of sol-gel processes for new membrane materials

- Pharmaceutical Manufacturer (Germany): Validation of the filtration of a highly potent active ingredient under GMP conditions

- Food Group (Italy): Development of a new plant extract line with minimal loss of aroma carriers

- Research Institute for Energy Materials (Switzerland): Analysis of filtered metal oxides in fuel cell systems

- Industrial Pilot Plant (Southern Germany): Development of an automated process for dewatering biopolymer suspensions

These application fields demonstrate: The JVK laboratory filter press is far more than an experimental device – it is a bridge between research and industrial reality.

Technological Innovations in Laboratory Filtration

- Small-format Membrane Filter Plates: Enable active post-pressing of the filter cake for maximum dewatering

- Digital Pressure and Temperature Monitoring: For reproducible experimental execution with optional data logging

- Modular Control Units: Connection to laboratory control systems possible (SCADA, PLC, OPC-UA)

- Exchangeable Plate Inserts: For quick conversion during media changes or method comparisons

- CIP-capable Designs: For automatic cleaning with hot water, steam, or chemicals

Additionally, JVK works with research partners on concepts for automated media analysis, where filtrate quality can be evaluated in real-time – a step towards the intelligent laboratory filter press.

Advantages over Conventional Laboratory Systems

- Process Proximity: Reproducibility of industrial conditions (pressure, volume, filtration behavior)

- Scalability: Results can be easily transferred to pilot and production plants

- Economic efficiency: Low media loss, reusability of filter cloths, durable components

- Safety: Closed systems minimize risk with toxic or reactive substances

- Flexibility: Quickly convertible for various media and experimental setups

Especially with complex or viscous media, the strength of the LFP becomes apparent: where classic filtration methods reach their limits, the JVK laboratory filter press delivers reproducible and meaningful results.

Maintenance, Lifespan, and Spare Parts Supply

JVK laboratory filter presses are designed for a long lifespan – even with intensive use in research or industry. Thanks to robust materials, modular construction, and high-quality components, many parts can be easily replaced or cleaned if necessary.

Maintenance Highlights:

- Quick plate change: Filter plates can be changed without special tools

- Easy cleaning: CIP-compatible designs enable chemical or thermal cleaning

- Stock availability: Replacement plates, seals, and filter cloths are permanently available

- Maintenance contracts on request: For research institutions with a plannable budget

JVK guarantees long-term availability for all components and continues to offer perfectly fitting replacement solutions for existing systems even after years.

Outlook: Automation, Digitalization, and Future Trends

- Digital process monitoring (IoT-ready)

- Interfaces for LIMS, SCADA, OPC-UA

- Sensor integration for pressure, temperature, pH, and conductivity

- Remote access and process data archiving

- AI-supported real-time media analysis

- Autonomous process control with adaptive parameters

- Self-optimizing filtration cycles for maximum efficiency

Especially for research and industrial process development, this opens up entirely new dimensions in data utilization, documentation, and reproducibility – crucial for regulatory processes and innovation leads.

Conclusion: JVK Laboratory Filter Presses – Innovation Meets Practice

JVK’s LFP laboratory filter press is more than a filtration tool – it is a platform for innovation, process optimization, and scientific insight. With its modular design, diverse configuration options, and the integration of state-of-the-art technology, it stands for efficiency, safety, and maximum result quality.

- Decades of experience in filter plate construction

- Tailor-made laboratory systems for all industries

- Highest material quality and workmanship

- Made in Germany with international support

Get a non-binding consultation now – our team of experts will gladly prepare a customized offer for your laboratory application.