Design & Planning

Design & Planning at JVK – Technical Excellence for Individual Filtration Solutions

Introduction: Why construction and planning are crucial

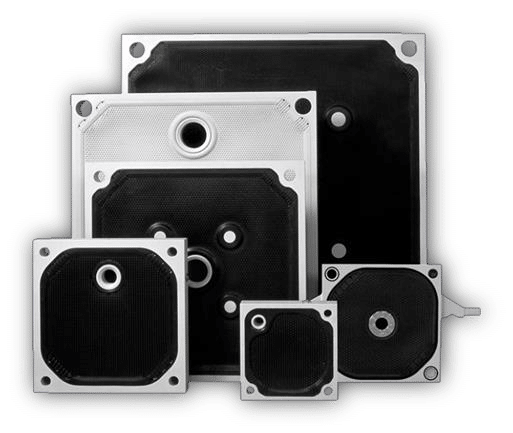

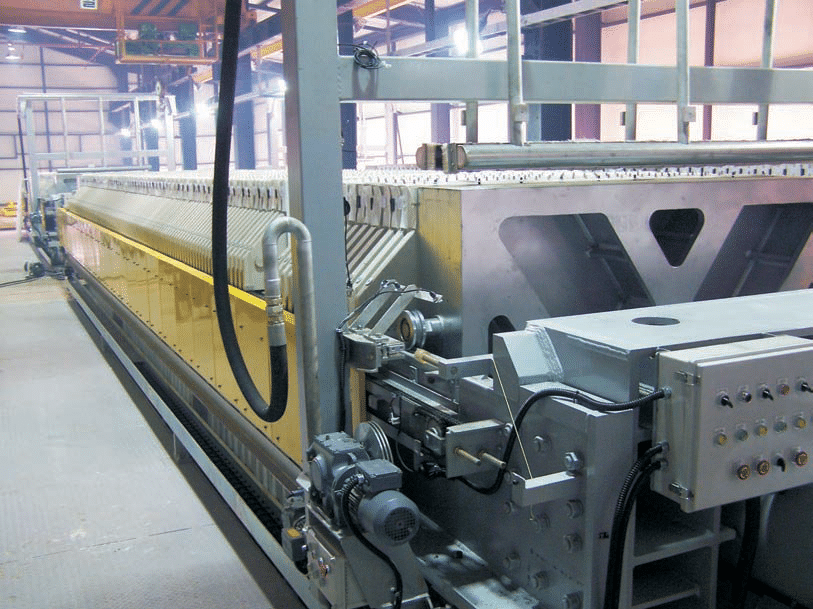

In industrial solid-liquid separation, the design of filter plates, membrane structures and filtration systems determines efficiency, service life and economy. JVK Filtration Systems offers technological expertise at the highest level – from the initial draft sketch to the detailed series construction. Our planning and development department specializes in individual customer solutions and sees itself as a bridge between process engineering requirements and manufacturing reality.

Technical basics – CAD, FEM & Simulation

Our design work is based on state-of-the-art software solutions:

- 3D-CAD construction with parametric systems

- FEM simulation for strength and deformation analysis

- Media flow analysis & cake formation modeling

- Flow optimization for filtrate discharge

- Load tests for pressing cycles and membrane elongation

This allows components to be tested for functionality, durability and process compatibility during the planning phase – without costly iterations in manufacturing.

Individual filter plate development – tailored to your process

JVK develops filter plates not from the catalog – but from your process data. These include:

- Pressure and temperature curves

- Media viscosity, particle sizes, pH values

- Filter cake geometry and volume

- Cycle times, rinsing intervals, backwashing

Based on these parameters, we construct filter plates with individually matched:

- Sealing systems (O-ring, tongue and groove, overhang)

- Drainage configurations (open/closed, central/eccentric)

- Drainage channels & structured support surfaces

- Membrane zones and expansion edges for defined deformation

Even complex sandwich systems, double membrane designs or shape transitions between chamber and membrane zones can be realized – with full compatibility with your press.

Tool development & mold making – directly from the design

A particular advantage at JVK: We not only develop the product, but also the right tool. Our designers work closely with the in-house mold making department, so that changes, adjustments or special solutions can be realized without any loss of time. Continuous CAD/CAM interfaces enable the direct transfer of 3D data into CNC manufacturing – for maximum precision and reproducibility.

Material selection & media-adapted construction

We already consider the appropriate material selection during the design phase. The following are available, among others:

- Polypropylene (PP-H, PP-R): Standard for most applications

- PVDF: high chemical resistance, temperature resistance up to 140 °C

- Special compounds: conductive, UV-stable, food-safe, ATEX-compliant

The geometry is adapted to the material in order to achieve maximum stability with minimum weight and optimum filter area.

Typical industry solutions & reference examples

Our planning expertise is successfully used in many industries:

- Chemical industry: Pressure-resistant membrane plates for aggressive media, modular plate systems

- Pharmaceutical industry: Cleanroom-compatible sealing systems, FDA-compliant materials

- Food production: Hygienic Design, CIP-compatible surfaces, closed filtrates

- Environmental technology: Recyclable filter plates for sewage treatment plants, sludge dewatering systems

Research & Development: Special plates for laboratory presses, modularly combinable

Whether large series or individual solution – we design exactly for your application.

Digitalization & Industry 4.0 in filter plate planning

Digital methods are also finding their way into filter technology. JVK is already focusing on:

- Digital Twin models for filter plates

- Integrated sensor planning for press conditions

- Predictive Maintenance concepts through design analysis

- Component documentation with QR codes & tracking

This enables proactive service, accelerated spare parts supply and data-based process optimization.

Inquiries

Contact us for a personal consultation or request a customized offer.

jvk@jvk.de or by telephone on +49 (0) 9172 707 0.

Additional Services

Consulting & Product Development

Holistic Service for Filter Plates & Filter Presses – From Concept to Maintenance

Design & Planning

Production & Outsourcing

Maintenance & Care

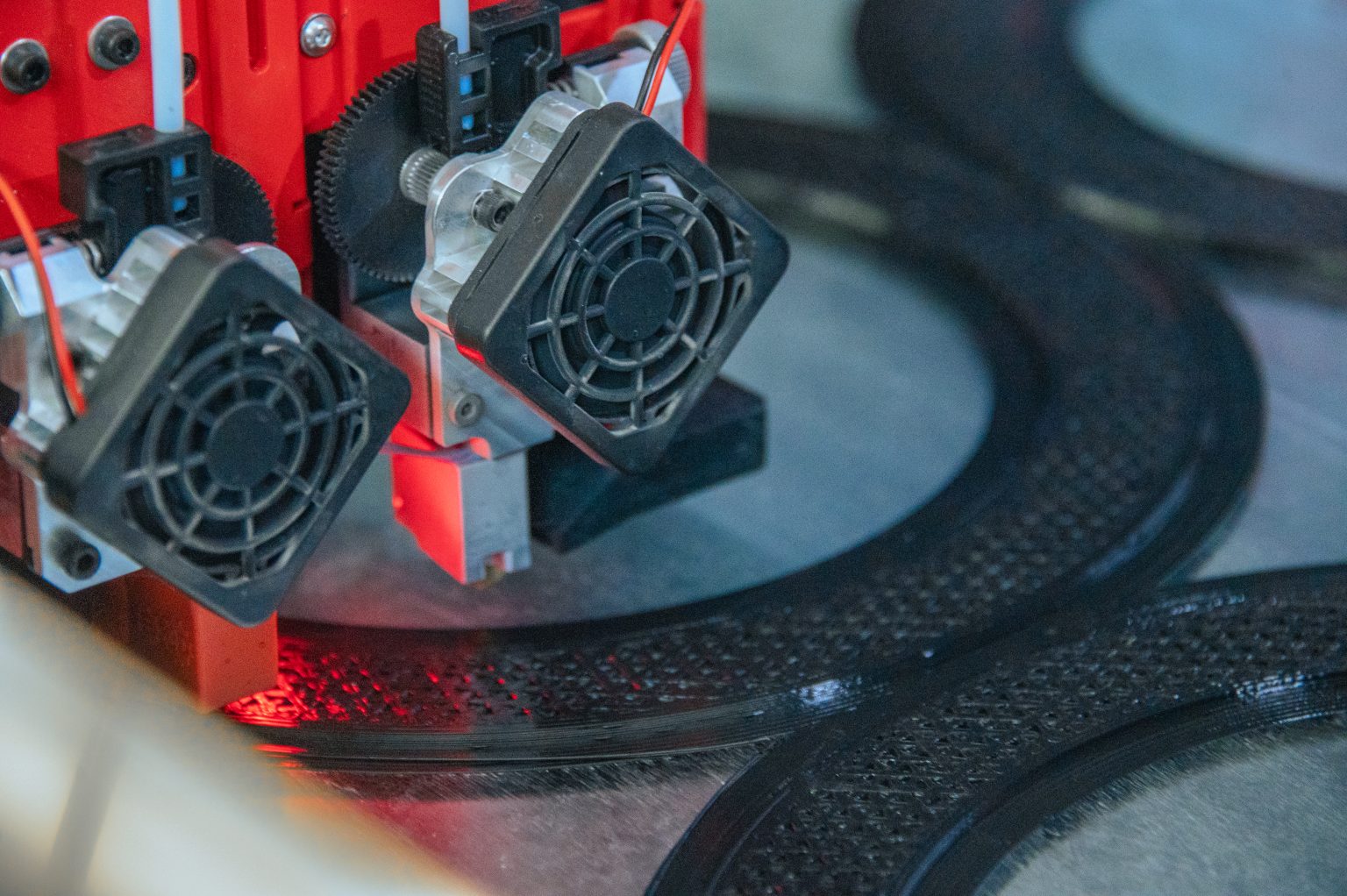

From the digital model to the real plate – manufacturing and process integration

After the completed construction, JVK directly transfers it to production. Our in-house mold making, coupled with CNC milling centers and thermoplastic processing, allows an agile implementation of the developed geometries. CAD/CAM connections are used, which automate the transition from the 3D model to the casting mold. The manufacturing process takes place under controlled conditions with complete traceability of all materials used.

Quality assurance along the production chain

JVK implements strict QS testing standards – both inline during production and in the final inspection:

- Dimensional accuracy and shape accuracy of the filter plate

- Functional tests of membrane elongation and sealing

- Chemical resistance depending on requirements (e.g. pH, temperature, solvents)

- Visual inspection according to VDI guidelines

- Serial numbers and material identification for traceability

Test certificates, FDA conformity certificates and material analyses are available on request.

Maintenance-friendly construction & spare parts management

We already consider the maintenance requirements of the later application during the planning phase. Designs with replaceable sealing elements, optimized cleanability or reinforced areas for cyclical loading are standard at JVK.

Our customers benefit from:

- Quick-change solutions for plates and membranes

- Exchange sets with documented setting data

- Maintenance recommendations based on real pressing cycles

- Spare part identification via serial number or QR code

Innovations in filter plate construction - thinking about tomorrow today

JVK continuously invests in new materials, plate types and design ideas: - Lightweight plates with increased stability

- Structure-optimized inner channels to reduce dead zones

- Combination plates (chamber + membrane) for flexible application profiles

- Integration of RFID tags for process monitoring

Many of these developments are the result of close cooperation with universities, research institutions and international partners.

Case study: From planning to implementation in practice

Example: A manufacturer of pharmaceutical intermediates required a highly resistant membrane filter plate for a special press system with increased back pressure. JVK developed a design with double-edge sealing, media-optimized drainage structure and PVDF membrane together with the customer. After laboratory tests and FEM simulation, the construction was manufactured, tested and delivered – with measurable increase in efficiency and increased number of cycles.

Future of planning – automation and AI-supported design

The future lies in forward-looking construction: JVK is currently testing AI-supported tools for automated filter plate dimensioning. Based on input parameters such as medium, temperature, target cycle time or cake thickness, the system suggests optimal design variants. This saves development time, reduces human error and opens up new possibilities in series individualization – keyword: batch size 1.

Conclusion: Construction at JVK – expertise that thinks along

Whether for new projects, retrofit solutions or research approaches – JVK offers you a development partnership that goes beyond pure product delivery. Our goal is to support your processes with technically sophisticated, maintenance-friendly and performance-optimized solutions. Talk to us – and let us work together to design what will be standard tomorrow.