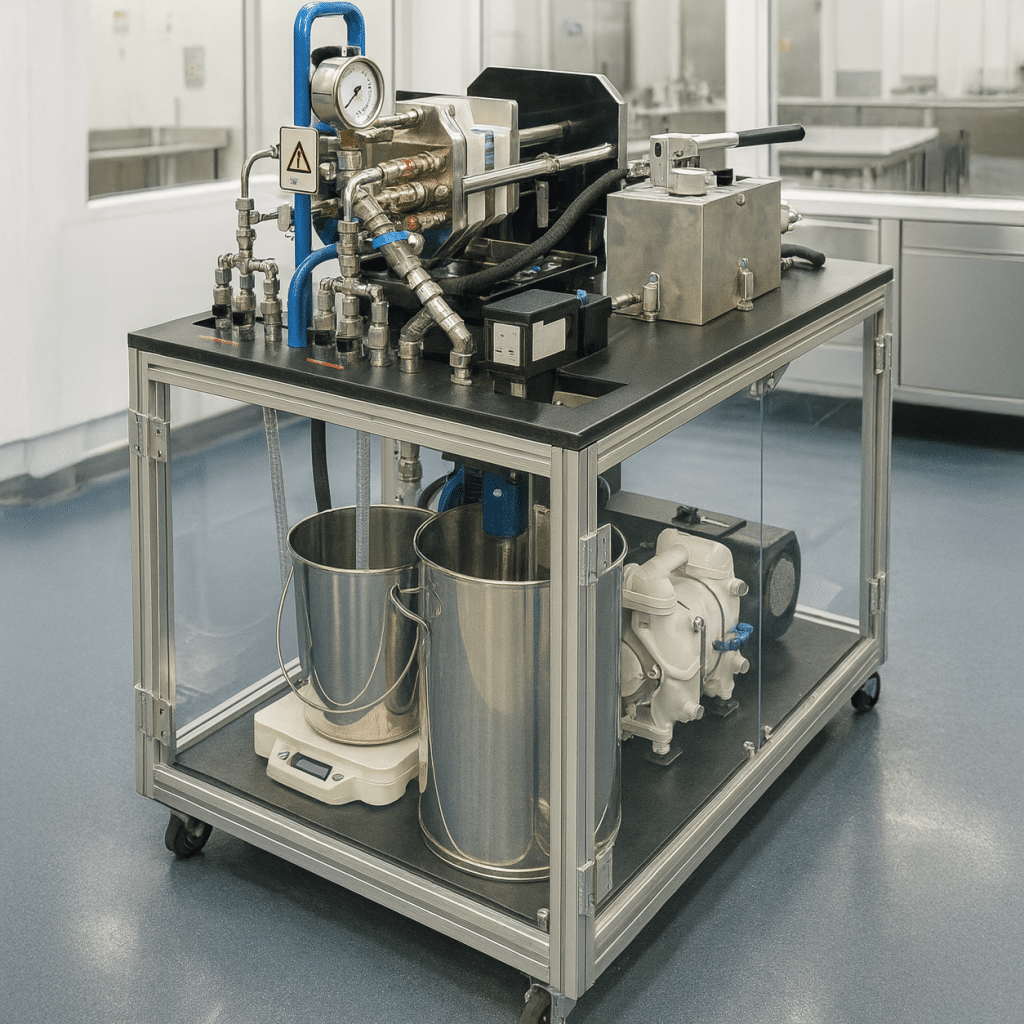

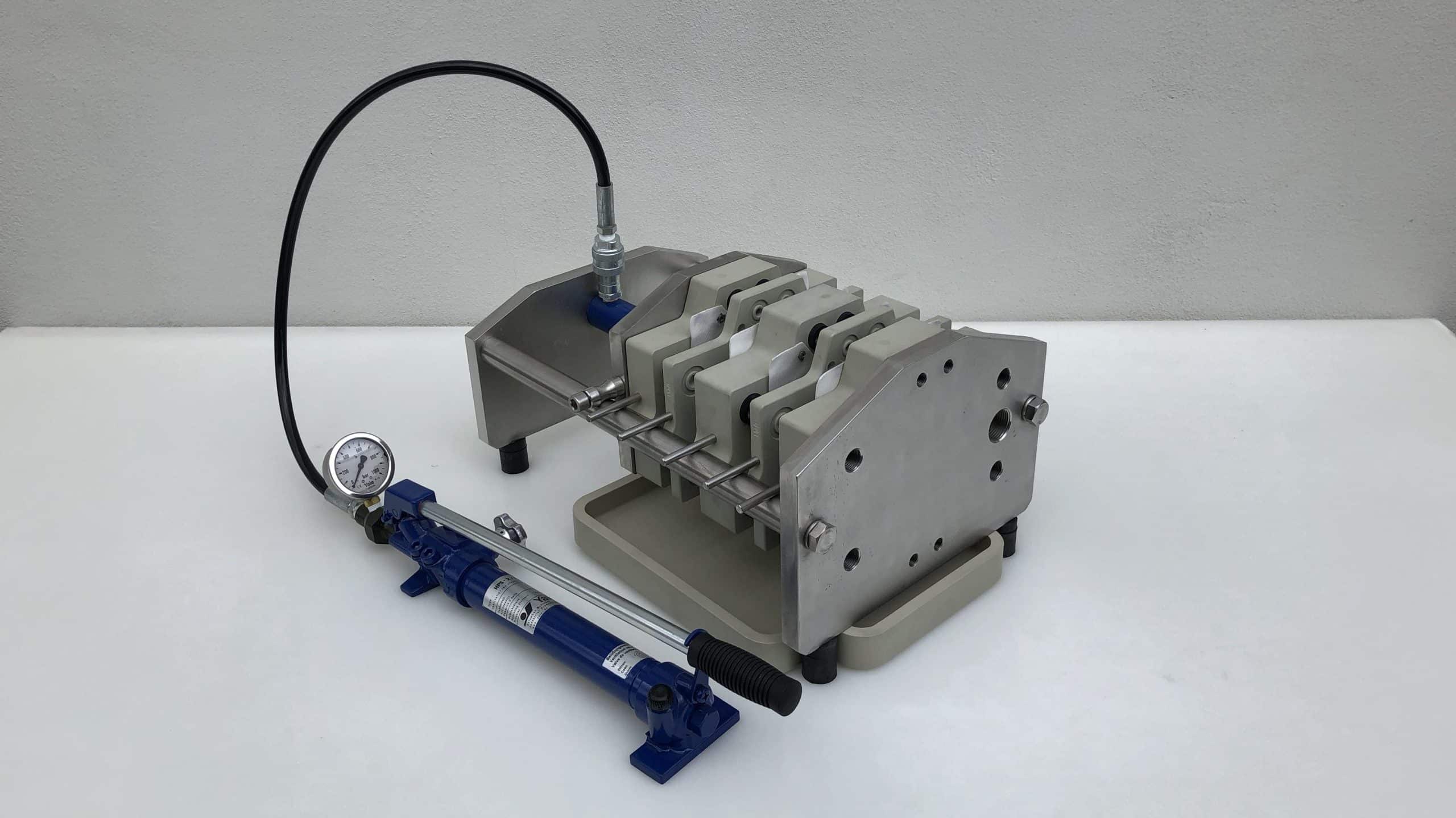

Laboratory Filter Presses – Precision on a Small Scale

Efficient Filtration for Research and Development

Our laboratory filter presses offer the same quality, robustness, and efficiency as our industrial models – in a compact format for laboratory use. They are ideal for experiments, product development, or process optimization.

Rent or buy – as required

JVK offers you laboratory filter presses for rent or purchase. This keeps you flexible – whether for short-term projects, feasibility studies, or permanent use in a technical center. And the best part: With every rented filter press, you also rent our decades of expertise.

Our experts advise you on selection, application, and optimization – practical, individual, and solution-oriented.

Service & Support

JVK supports you from selection to commissioning of your laboratory filter press. Whether consulting, spare parts, or maintenance – we ensure that your experiments run smoothly.

Consulting & Product Development

Holistic Service for Filter Plates & Filter Presses – From Concept to Maintenance

Design & Planning

Design & Planning at JVK – Technical Excellence for Individual Filtration Solutions

Production & Outsourcing

International Manufacturing & Outsourcing at JVK – Your Extended Workbench for Plastics Technology, Prototyping, and 3D Printing

Maintenance & Care

Maintenance & Care of Filter Plates – Why JVK's Services Secure Your Production

Customer service - more than just support

Your process drives us

JVK stands for more than just products – we stand for functional processes. Our customer service supports you personally, practically, and solution-oriented, ensuring your filtration performs exactly as it should from the start.

Process-Oriented Consulting – individual instead of standard

Every process is unique. That is why we take the time to understand your process specifications in detail – from solids loading to the desired dry substance content. Based on this, we develop the optimal filtration solution together with you – precisely tailored to your requirements.

Commissioning with Expertise – Proper Use of Filter Elements

Our experts support you with the correct commissioning of your filter elements – whether for initial use or replacement. Ensuring everything fits from the start: from sealing to throughput.

Effective Optimization – for greater operational efficiency

Is your process running, but not yet perfectly? We help you analyze, adapt, and make your filtration processes more efficient. Whether shorter cycle times, lower energy consumption, or better filtrate quality – we show you where the potential lies.

In short: We don’t think in products – we think in processes. And our service doesn’t end with the sale – it truly begins there.

JVK Health Check –

Extend Performance and Warranty

Proactive Service. Extended Security.

With the JVK Health Check, you get the most out of your filter elements – and simultaneously secure your future a bit more.

Because every time you have your filter plates inspected through our certified Health Check, your warranty period is automatically extended. This is our promise for maximum security and confidence in your technology.

Condition Analysis of Your Filter Plates

directly on-site

Inspection for material fatigue, cracks, or leaks

Evaluation of process parameters and load profiles

Documentation & Recommendation

regarding replacement, maintenance, or continued use

Your Benefits at a Glance

- Extended warranty period with every check – completely automatically

- Early detection instead of failure – avoid downtime through targeted prevention

- Transparent recommendations – no surprises, clear facts

- Value protection for your investment – and a good feeling with every cycle

JVK Health Check: The easiest way to keep your processes running – and let your warranty grow with them.

Don’t just let your filter plates age. Have them checked. For more efficiency, security, and confidence.