Filtration for

Recycling / Treatment

Recover raw materials. Keep water in circulation. Operate systems safely.

What Our Customers Value

Performance and quality

High throughputs, stable cycles, low residual moisture, clear filtrate

Robustness

Resistant materials for aggressive media (alkalis, acids, salts)

Cost-effectiveness

Short cycles, long service life, low chemical and energy consumption

Security and compliance

Process-reliable filtration with verifiable quality

Typical recycling application

Battery recycling (e-mobility)

From black mass to valuable material recovery.

In hydrometallurgical recycling, defined solid/liquid separation steps are crucial: from the separation of graphite/carbon black fractions and the clarification of leach solutions to the filtration of precipitated metal hydroxides (e.g., Ni, Co, Mn).

Your Goals

- Clear filtrate for stable downstream steps (solution extraction, crystallization)

- Low residual moisture for better cake handling and drying

- Chemical & temperature-resistant components

- ATEX/Safety aspects depending on the process step

JVK® solution modules

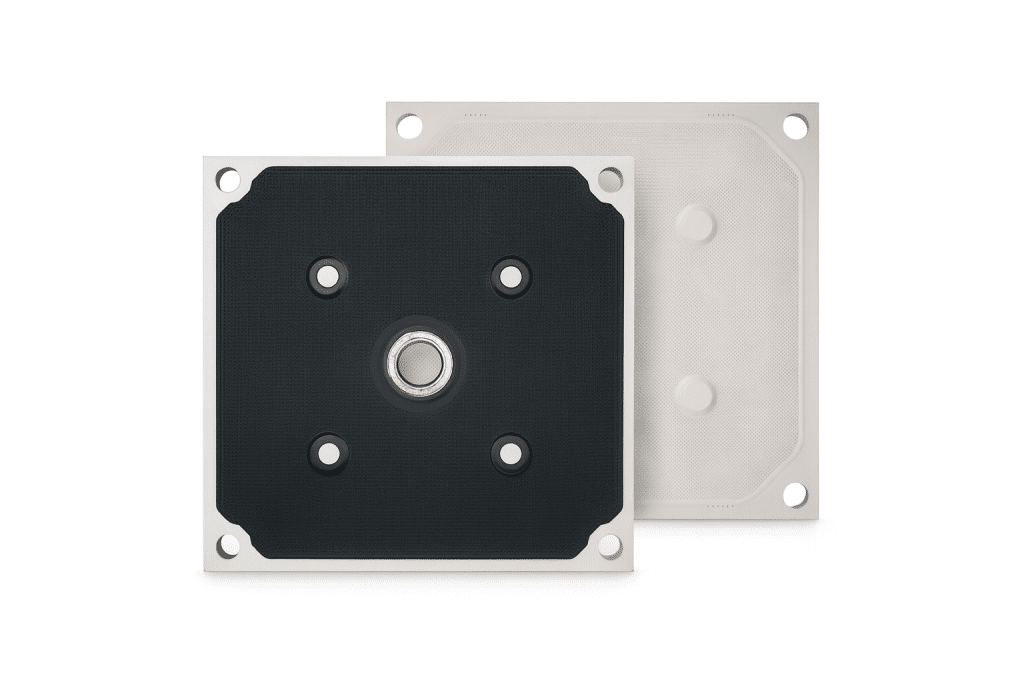

- Membrane filter plates to shorten cycle times and reduce residual moisture

- Filtertch engineering suitable for PSD/particle shape (graphite, metal hydroxides) and desired retention

- Materials: PP/PVDF for aggressive media; membranes e.g., EPDM/NBR depending on medium/temperature

- Washing & drying strategies (filter cake washing, pressure/air drying)

Typical recycling application

Wastewater Treatment

- Dewatered sludges with high dry solids content (lower disposal costs)

- Clear filtrate for recirculation or discharge compliance

- Simple maintenance and short downtimes

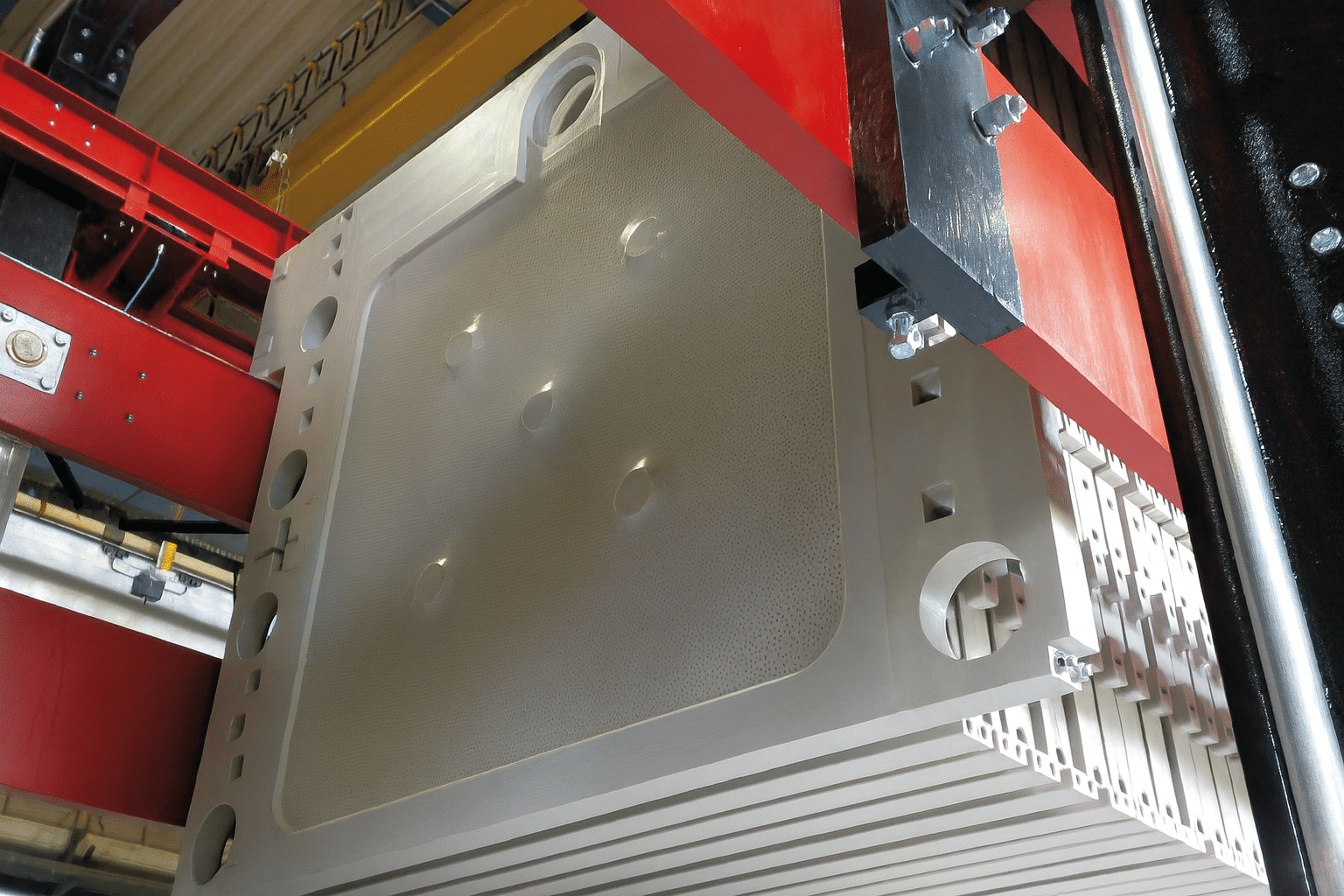

- Chamber or membrane filter plates depending on the cost target/performance requirement

- Filter cloth selection (weave, yarn count, finish) optimized for retention/permeability

- Chemical-resistant materials (TPE, EPDM, NBR, FKM, PP (welded-in) for variable pH/media conditions

Typical recycling application

Offshore and drinking water

- Stable, low-maintenance systems with high plant availability

- Marine-grade materials against salt and chloride exposure

- Compact, energy-efficient solutions

- Corrosion-resistant materials (PVDF, PP) in saline environments

- Membrane filter plates for short cycles/low residual moisture in confined spaces

- Service concepts for remote locations (quick filter cloth/gasket change, spare parts packages)

Are you planning a recycling, wastewater, or offshore project?

We examine your data, recommend the appropriate configuration, and deliver a reliable, economical solution.

How We Work Together

- Requirements and samples – target values, media, framework conditions

- Design – plates / cloths / sequences suitable for medium and target parameters

- Practical tests/Sampling – validated parameters with documentation

- Implementation and training – fast commissioning, safe operation

- Service & Availability – Wear parts, monitoring, operational optimization

Your added value with JVK®

- Scalable: from pilot to series production

- Plannable: documented quality and compliance

- Partnership-based: dedicated contacts, short communication channels

- Made in Germany

Flexible in spare parts service

You need replacement elements – that fit perfectly and are compatible? JVK® supplies OEM-compatible chamber and membrane filter plates, seals and filter cloths for the most common systems – across all industries and documented.

Formats & materials:

150-4000 mm, in all standard formats and designs, various sealing concepts: PP/PVDF, membranes e.g. EPDM/NBR, FKM, TPE.

Optional: upgrades for greater efficiency and process reliability

- SnapFit®: Screwless connecting element for attachments and filter cloth fastening – reduces downtimes during operation.

- Post-press indicator: Early detection of process weaknesses(e.g. defective membranes and uneven filter cake build-up) for targeted optimization and more stable cycles.

Your advantage: OEM-compatible, a perfect fit – with useful upgrades for operation & quality.

Your advantage: OEM-compatible, a perfect fit – with useful upgrades for operation & quality.