Mining / Minerals

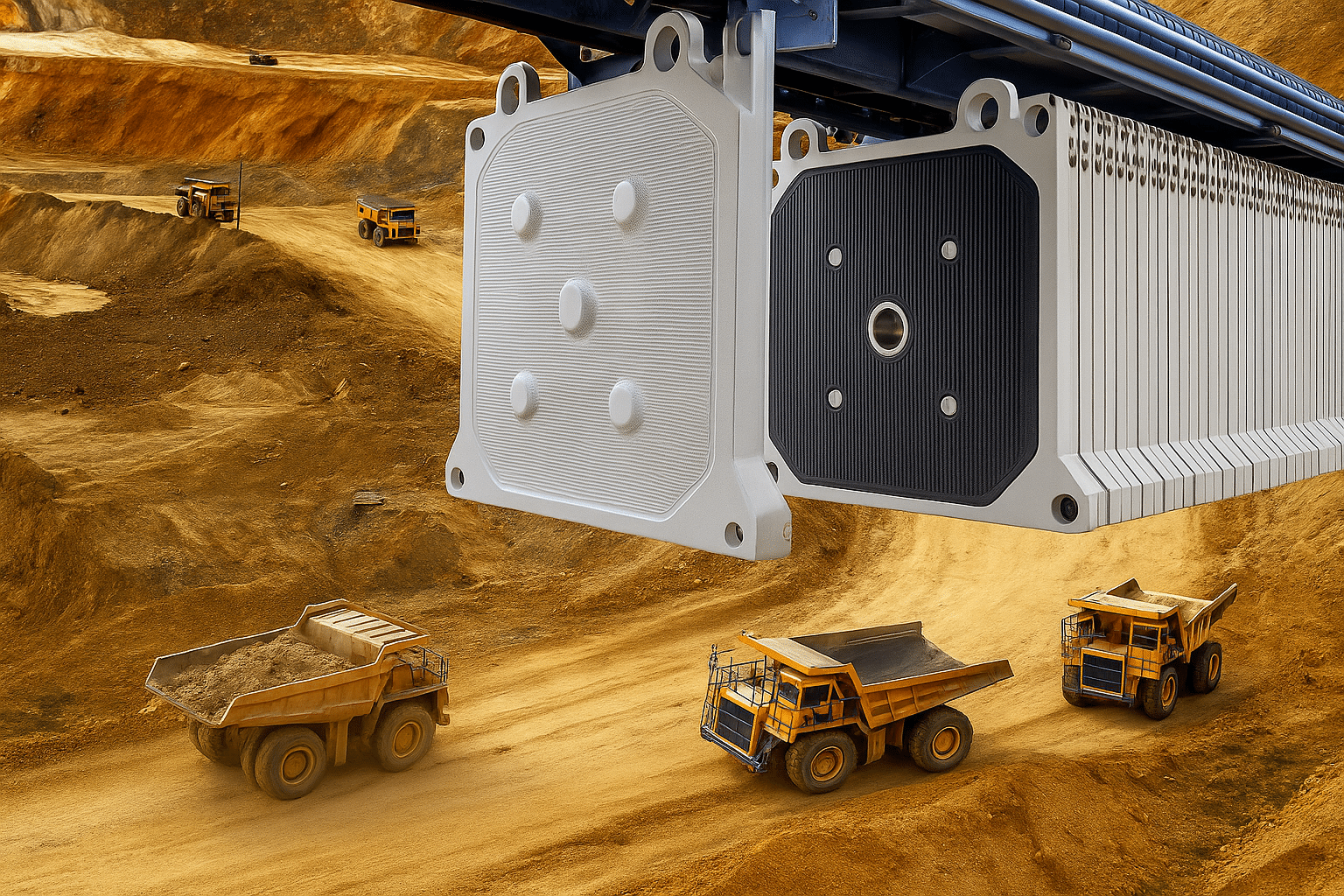

Filtration Under Harsh Conditions – Reliable, Efficient, Predictable.

In ore processing, tailings and process water, robust, reproducible filtration determines yield, operating costs and safety. JVK® combines material expertise, membrane technology and application-oriented tests to create solutions that work permanently in harsh environments – for clear filtrates, dry cakes and high system availability.

What Matters for Operators

- Performance and quality: High throughput rates, stable cycle times, optimum residual moisture in the cake and clear filtrate with low turbidity.

- Robustness: Abrasion and corrosion-resistant components for abrasive slurries, changing solids contents and temperature fluctuations.

- Cost-effectiveness: Low operating costs thanks to short cycles, efficient washing sequences and quick filter cloth changes.

- Safety and environment: Maximum water recovery, reliable tailings drainage and minimized environmental impact.

JVK's Solution Approaches

- Filter plate and membrane technology: Chamber or membrane filter plates to shorten the cycle time and reduce residual moisture.

- Filter cloth engineering: Selection of weave, yarn count and finish to suit PSD/ore character, desired retention and permeability.

- Filter cake washing and drying design: Optimized channel guidance, washing sequences and optional pressure/air drying for better product quality and low wear.

- Material expertise: Media and temperature-resistant thermoplastics (e.g. PP, PE, PVDF) as well as diaphragms made of EPDM, NBR, FKM, TPE and PP.

- Process variables: Post-compression indicator (compression volume during operation with water)

Typical Areas of Application

Ore Processing / Concentrates

Tailings Dewatering and Stabilization

Process and Recirculation Water

By-product and Valuable Material Recovery

Design and validation

We start with material and process-related parameters (solids %, pH, temperature, reagents), define target values (throughput, residual moisture, filtrate quality, degree of washing) and design filter plates, filter cloths and process control accordingly.

Practical tests and sampling verify the parameters. We document the results transparently for operations and audits.

Availability and service

Wear-optimized components, easily accessible wear points and quick filter cloth changes reduce downtimes. Spare parts and support can be planned – for high system availability over the entire life cycle.

In short: More tonnage with stable cycles, drier filter cake and cleaner filtrate – at lower total cost of ownership.

Flexible spare parts service

You need replacement elements – that fit perfectly and are compatible? JVK supplies OEM-compatible chamber and membrane filter plates, seals and filter cloths for the most common systems – across all industries and documented.

Formats & materials:

150-4000 mm, in all standard formats and designs, various sealing concepts: PP/PVDF, membranes e.g. EPDM/NBR, FKM, TPE.

Optional: upgrades for greater efficiency and process reliability

- SnapFit® –Screwless connecting element for attachments and filter cloth fastening – reduces downtimes during operation.

- Post-press indicator: Early detection of process weaknesses(e.g. defective membranes and uneven filter cake build-up) for targeted optimization and more stable cycles.

Your advantage: OEM-compatible, a perfect fit – with useful upgrades for operation & quality.