Filtration in the

food industry

Filtration with hygiene, efficiency and availability

Common Requirements:

- Food-compliant materials and a design optimized for hygiene

- Stable cycles and high throughput, clear filtrates, low residual moisture

- CIP capability (hot caustic/acid), traceable quality

- Quick maintenance, easy filter cloth change, long service life

- Predictable availability (spare parts, service)

- Replaceable or welded-in membrane filter plates possible

JVK Response

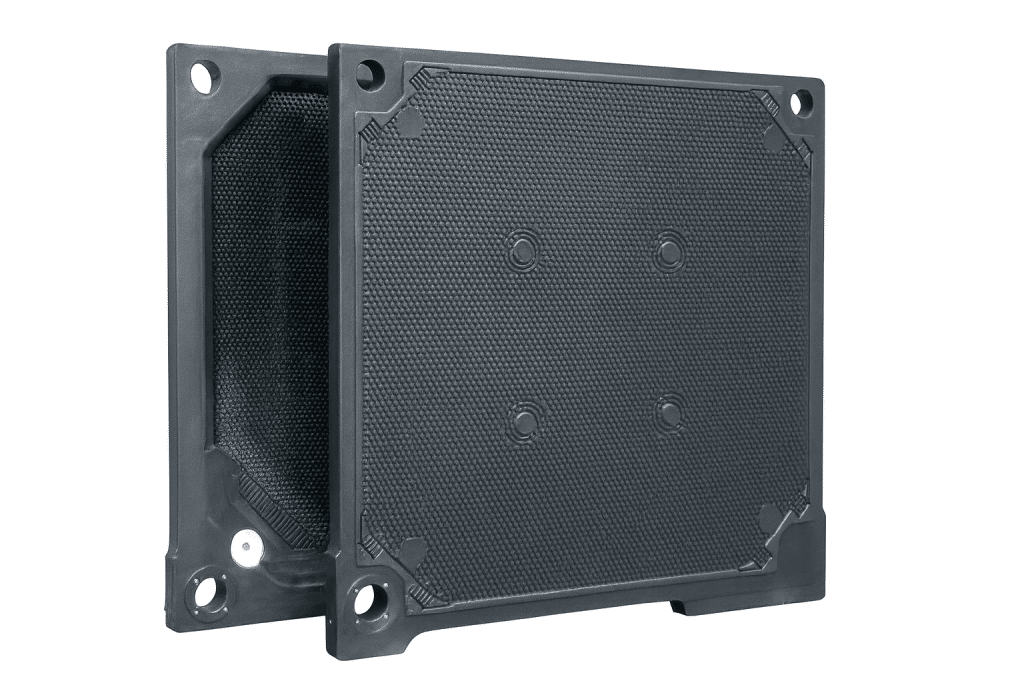

Chamber or membrane plates

Cost vs. Performance

Squeeze pressure up to 50 bar

Filter cloth engineering

Adapted to PSD/particle shape and desired retention/permeability

Materials

PP/PVDF for media/temperature-resistant components; EPDM/NBR/TPE diaphragms e.g. for hot liquor

Sequences

Filter cake washing & pressure/air drying if required

CIP-friendly design

and quick filter cloth change concept

Repressing indicator

For rapid detection of cracks in the membranes

Filtration with hygiene, efficiency and availability

Typical food application

Breweries

In breweries, clean, reproducible filtration determines product quality, operating costs and availability. Whether kieselguhr/perlite sludge, PVPP regeneration or surplus yeast: processes must be hygienic, CIP-compatible and economical – with clear filtration rates for recirculation or legally compliant discharge. JVK® supplies robust, food-grade solutions that enable low residual moisture, stable cycles and easy handling in everyday life.

What is required?

- Dewatering of filtration aids & slurries (diatomaceous earth/perlite, PVPP, yeast)

- Clear filtrate for recirculation or discharge compliance

- Food hygiene & CIP: Resistance to hot caustic/acid, easily cleanable surfaces

- Low residual moisture → lower disposal costs, better handling

- Compact, reliable systems with minimal downtime

How does JVK® solve this?

- Membrane filter plates for shorter cycles and lower residual moisture (especially PVPP/diatomaceous earth sludge)

- Monofilament cloths for good filter cake discharge; cloth selection tailored to retention & permeability

- Materials & seals resistant to CIP media (PP/PVDF, EPDM, TPE)

- Closed filtrate guidance, drip/splash protection, optional automatic cake discharge/cloth cleaning

- Quick filter change and easily accessible wear points for quick maintenance

Typical food application

Sugar Industry (Beet/Cane)

In sugar production, high temperatures, alkaline conditions and abrasive particles come up against tight campaign schedules. Carbonation and lime sludge must be safely dewatered, sugar losses minimized and washing degrees reliably achieved. JVK® combines robust materials with application-specific filter plates to ensure the right throughput, washability and availability throughout the entire campaign.

What is required?

- Filtration of carbonation/lime slurries and other process slurries

- High temperatures & alkaline conditions, abrasive particles

- Sugar recovery: good washability, low sugar losses

- High availability over long campaigns, easy maintenance

- Low residual moisture for lower disposal costs / better logistics

How does JVK® solve the

- Large-format chamber or filter membrane presses with suitable filter cake thickness for high throughputs

- Filter cake washing sequences for sugar recovery, optimized channel routing

- Filter cloths for sticky/fine-grained carbonation sludge (retention vs. throughput matched)

- Media/temperature-resistant materials, EPDM diaphragms for hot caustic solutions

- Wear protection & robust feed zones; quick filter cloth change for campaign operation

Service and availability

- Start-up/practical tests for parameterization, documentation for QA/compliance

- Spare part packages & training for operating teams, remote support

- Optimization during operation (filter cloth recommendation, sequences, maintenance intervals)

Flexible spare parts service

You need replacement elements – that fit perfectly and are compatible? JVK® supplies OEM-compatible chamber and membrane filter plates, seals and filter cloths for the most common systems – across all industries and documented.

Formats & materials:

150-4000 mm, in all standard formats and designs, various sealing concepts: PP/PVDF, membranes e.g. EPDM/NBR, FKM, TPE.

Optional: upgrades for greater efficiency and process reliability

- SnapFit®: Screwless connecting element for attachments and filter cloth fastening – reduces downtimes during operation.

- Post-press indicator: Early detection of process weaknesses(e.g. defective membranes and uneven filter cake build-up) for targeted optimization and more stable cycles.

Your advantage: OEM-compatible, a perfect fit – with useful upgrades for operation & quality.