Filtration in the

chemical industry

Filtration from the heart of German chemistry – shaped by practical experience, partnerships, and process expertise.

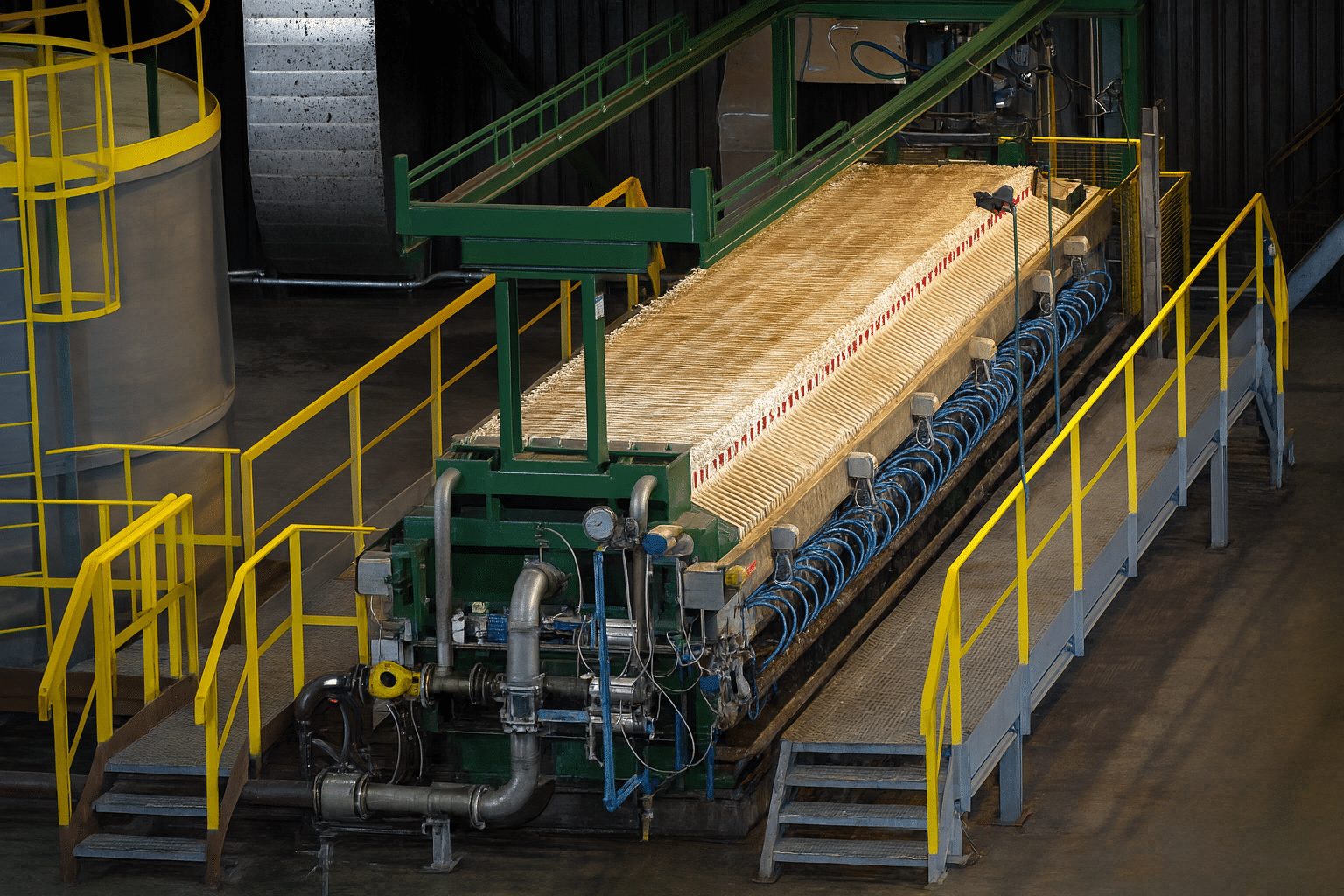

Modern solid/liquid separation was significantly advanced in the German chemical industry.

BASF was an early industrial user of filter presses, while in 1962 Joh. Jac. Vowinckel – the origin of JVK® – started the first series production of filter plates made of polyolefins. This shared industrial ecosystem continues to shape JVK’s understanding of chemical raw materials, aggressive media and process-reliable filtration to this day.

What do chemical companies require?

Chemical and temperature resistance

Durable materials resistant to acids/alkalis, solvents, salt/oxidation media; safe at elevated temperatures.

Process Performance

High throughputs, stable cycles, low residual moisture, clear filtrate for downstream steps (extraction, crystallization, drying).

Safe Operation

Optional ATEX/ESD-compliant design, low-leakage sealing concepts, safe cake handling.

Maintainability and availability

Fast filter cloth/membrane changes, robust filling/drainage zones, long service life.

Scalability

From pilot to series production, flexible adaptation to fluctuating suspension characteristics (PSD, solids %, viscosity).

How does JVK® solve this?

Technological

Expertise

Highest

Quality Standard

For us, quality is not a promise, but a measurable value.

Our filter elements are manufactured according to the strictest standards to ensure maximum durability, reliability, and efficiency.

We exclusively use first-class materials and continuously invest in the latest technologies to ensure manufacturing precision and consistently high product quality – from the initial development idea to final inspection.

Customer-Centric

Solutions

Every filtration task is unique – and we design our solutions just as individually.

Thanks to flexible manufacturing, we can specifically address individual customer requirements and precisely adapt products to your processes.

Our experts offer comprehensive consultation – also directly on-site – and are ready with fast, practical solutions to resolve filtration problems and sustainably optimize processes.

To the point: JVK filter elements for the chemical industry: clean filtrate, low residual moisture, robust availability.

Typical chemistry application

Precipitation & crystallization filtrates

Context: In inorganic/organic chemistry, defined solid/liquid separation steps determine the purity of downstream stages (extraction, ion exchange, crystallization/drying).

What is required?

- Clear filtrate with low fine particle content for stable further processing

- Good washability of the filter cake (high product purity, low mother liquor residue)

- Optimum residual moisture for efficient drying/handling and further processing

- Chemical & temperature-resistant components

How does JVK solve this?

- Chamber or membrane filter plates to shorten cycle times and reduce residual moisture

- Filter cloth engineering (weave/yarn/finish) suitable for particle shape & PSD → Retention vs. permeability optimized

- Filter cake washing sequences with suitable channel guidance; optional pressure/air drying

- Materials such as PP/PVDF/PE; diaphragms e.g. EPDM/NBR/FKM/TPE depending on medium/temperature

Typical chemistry application

Catalyst & adsorbent recovery (e.g. Pd/C, Ni, activated carbon)

Context: Heterogeneous catalysts/adsorbents must be separated with minimal loss and often reused – with high fine particle retention and safe handling. What is required?

- High retention of fines (minimal metal/catalyst losses) with stable throughputs

- Cleanability/CIP capability with frequent campaign changes

- Finely tuned filter cloths (monofilament/multifilament, surface finish) for clean discharge & high solids retention.

- Use of membrane filter plates to shorten process times, increase efficiency with the same dry matter content as conventional systems.

- Sealing/edge concepts for low-leakage operation; optional conductive/ESD-compliant designs

- CIP-friendly design and quick change concepts for filter cloths.

Typical chemistry application

Pigment, filler & additive slurries (e.g. TiO₂, Fe oxides, CaCO₃)

Context: High solids content, partly abrasive or sticky systems – requiring robust systems, constant cycles, and economical dewatering.

What is required?

- High throughputs with stable cycle times

- Abrasion resistance in feed/discharge zones, robust materials

- Low residual moisture for logistics/further processing, good washability depending on quality target

How does JVK solve this?

- Large-format filter plates with suitable filter cake thickness; membrane squeeze for residual moisture benefits

- Wear-optimized design (flow guidance, liner) for abrasive media

- Filter cloth selection against clogging/filter cake caking (suitable fabric & finish)

Joint added value with JVK®

Clear filtrate, dry filter cakes, documented process stability – with chemical-resistant materials, tried-and-tested washing/drying sequences and service for high system availability.

Flexible in spare parts service

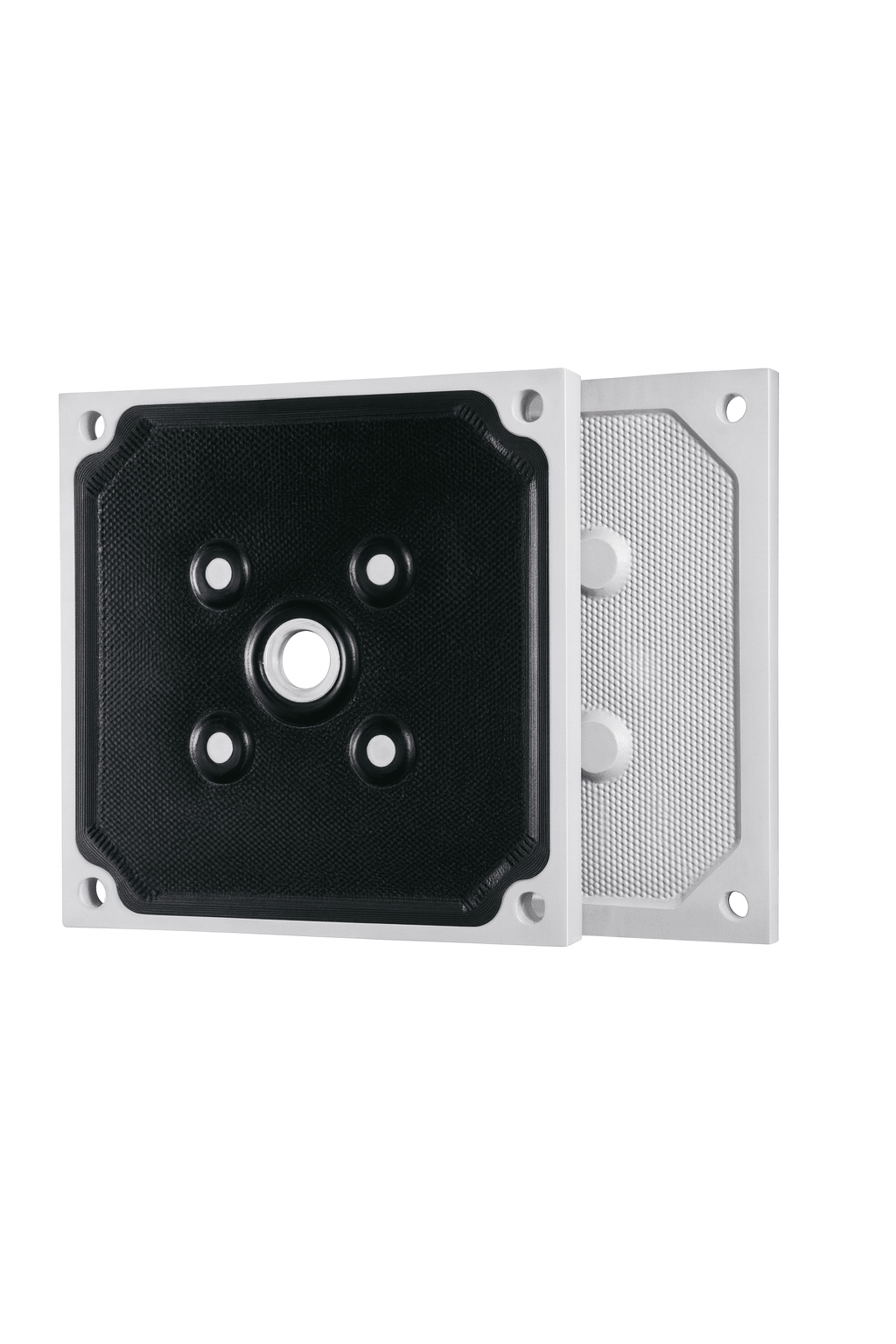

You need replacement elements – that fit perfectly and are compatible? JVK supplies OEM-compatible chamber and membrane filter plates, seals and filter cloths for the most common systems – across all industries and documented.

Formats & materials:

150-4000 mm, in all standard formats and designs, various sealing concepts: PP/PVDF, membranes e.g. EPDM/NBR, FKM, TPE.

Optional: upgrades for greater efficiency and process reliability

- SnapFit® -Screwless connecting element for attachments and filter cloth fastening – reduces downtimes during operation.

- Post-press indicator: Early detection of process weaknesses(e.g. defective membranes and uneven filter cake build-up) for targeted optimization and more stable cycles.

Your advantage: OEM-compatible, a perfect fit – with useful upgrades for operation & quality.