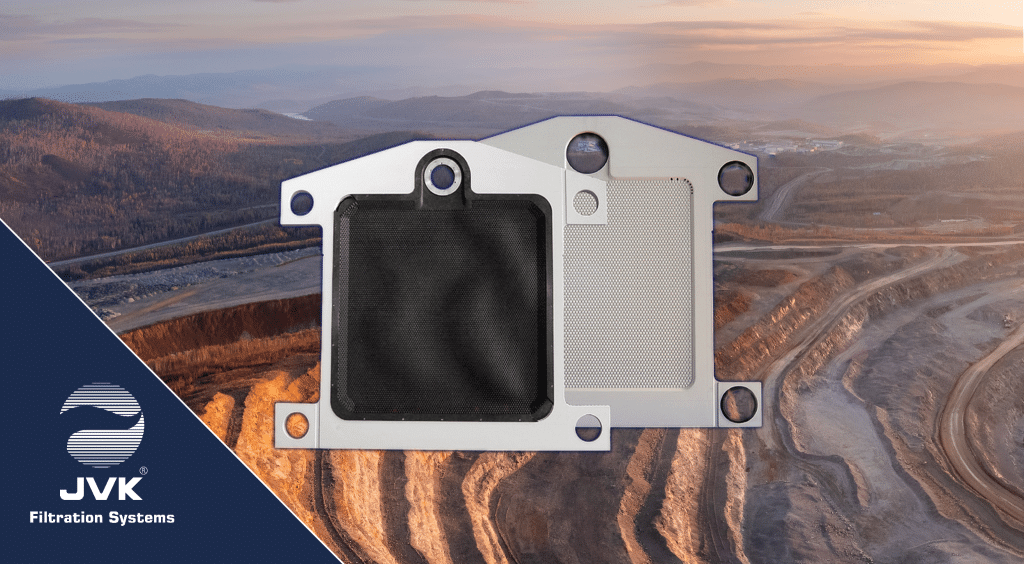

Sala Mining Plate

for industrial use

Sala Mining Plate

Size: 1500×1500 mm

Applications: Mining, Chemical Industry, Metal Processing

Features:

- replaceable membrane

- Replaceable filtrate discharge

JVK® SALA Plate – Example SALA 1500

Compatible. Robust. Mining-proven.

The JVK® SALA plate is the perfectly matched solution for filter presses of the (former) SALA/Metso series. Taking SALA 1500 as an example, JVK® manufactures chamber, membrane chamber (MRP), and membrane combination plates (MCP) that are mechanically and hydraulically compatible with the system – including suspensions, drilling patterns, and sealing concepts.

Benefits at a Glance

- Plug & Play Compatibility: Direct replacement in existing SALA presses without modifications.

- Long Service Life: Flow-optimized channels and abrasion-resistant materials for abrasive mining media.

- Increased Process Reliability: Optional post-pressing (MRP/MCP), efficient cake washing, thermal drying/temperature control.

- Consistent Quality: Dimensionally accurate manufacturing, reproducible cake thickness, secure sealing.

Technical Specifications (SALA 1500 – Exemplary)

- Plate Size: 1500 mm

- Plate Types: Chamber, MRP, MCP

- Materials: PP or PVDF; membrane e.g., TPE/EPDM/NBR

- Operating Pressure: depending on type/material; dewatering possible with MRP/MCP

- Options: Center/Corner Inlet, Cake Washing, Thermal Drying/Temperature Control

Applications: Concentrates, Tailings, Ore Processing, Residue Dewatering – wherever reliable operation of SALA presses is required.