Mining Plate

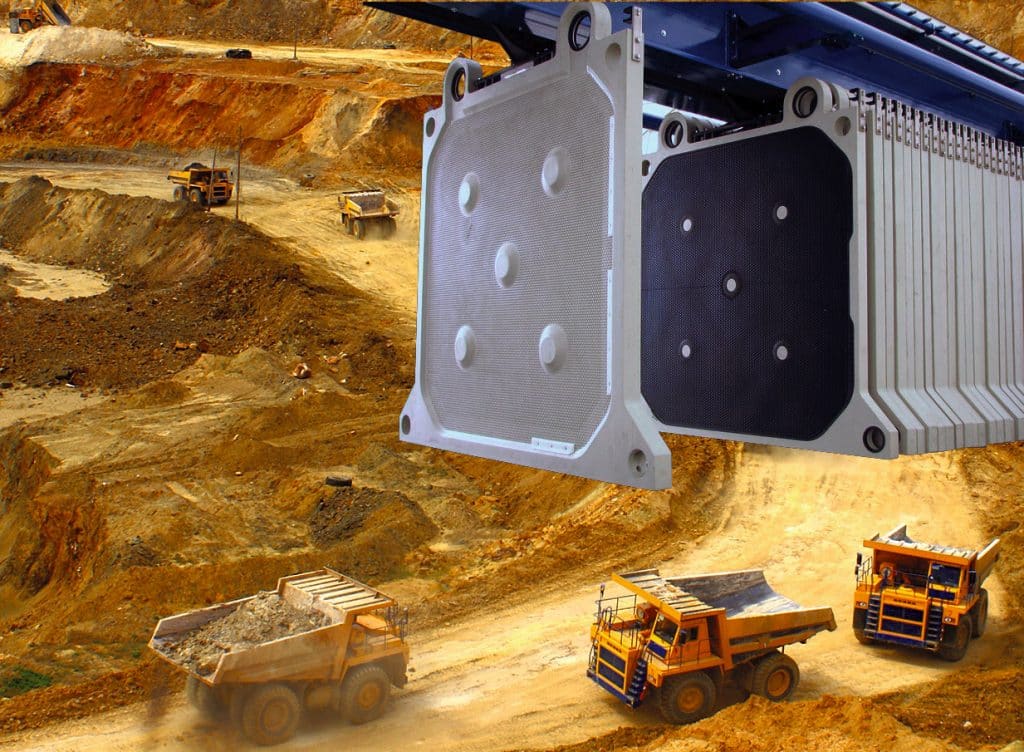

Mining plates

Customized filter press plates for the toughest mining applications

JVK® develops and manufactures mining plates for maximum service life, fast dewatering, and reproducible filtrate results. Whether custom-made for new projects or compatible with Metso/SALA and Ishigaki – we deliver the precisely fitting solution for your filter press.

JVK® Mining Plates

Custom-Made: the Best Solution is Yours

- Geometry & Connection Diagrams: Center/Corner inlet, additional washing and rinsing channels, optimized drainage surfaces.

- Cake Thickness & Surfaces: Defined chamber heights, structured sealing and dewatering zones for fast cake formation.

- Materials: PP or PVDF; membranes, e.g., TPE/EPDM/NBR – matched to temperature, pH, chemicals, and abrasion.

- Process options: Cake washing, repressing / squeezing (MRP/MCP), thermal drying / tempering.

- Target Values: Short cycle time, low residual moisture, high plant availability.

Metso/SALA Type – Plug-and-Play

JVK® supplies SALA-compatible plates (e.g., 800/1000/1200/1500 mm) with matching geometry, suspension, and drilling patterns. Ideal for retrofit or conversion to membrane technology without machine modification.

Ishigaki Type – Custom-fit Compatible

For Ishigaki presses, you receive chamber, membrane, and combination plates with a project-specific fit. Options for washing, temperature control, and special media included.

Advantages in Mining

- Long Service Life: Low-wear plastics, reinforced edges, large flow cross-sections.

- Performance & Quality: Fast dewatering, uniform cake, stable filtrate quality.

- Process Reliability: Low-leakage sealing concepts, robust membranes, reliable pressure ratings.

- Service: Design for cake thickness, media resistance, material, and seal selection.

Applications

Ore and concentrate filtration, tailings dewatering, process water treatment, recycling, and other solid/liquid separation tasks in mining.

Start Project Now

Please provide press type/size, inlet type, cake thickness, medium/temperature/pH, and target values (residual moisture, cycle time). We will create a custom specification with material recommendation and service life estimation.

FAQ

What Distinguishes JVK® Mining Plates from Standard Plates?

Customized geometries, optimized channel design, and material resistance for abrasive media shorten cycles and extend service life.

Are JVK® Plates Compatible with Metso/SALA and Ishigaki?

Yes. JVK® manufactures compatible chamber, membrane, and combination plates in common sizes – plug-and-play in existing presses.

What Materials are Available?

PP/PVDF for plate bodies; membranes, e.g., TPE, EPDM, or NBR – depending on temperature, pH, and chemicals.