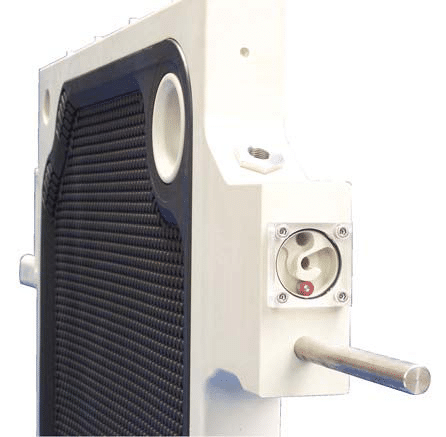

Repressing indicator

Repressing indicator

Application:

- Indication of the completion of the dewatering process

- Localization and detection of defective membranes and leaks

- Gas (e.g., air) or liquid (e.g., water, oil) as dewatering media

JVK® Repressing indicator

Features and Benefits

- Indicates the end of cake compression, thereby minimizing dewatering and cycle times.

- Optimizes press capacity, especially with changing products.

- Reliably and promptly detects membrane leaks.

- Warns of potential plate deformations and resulting production disruptions.

- Can also be retrofitted to existing membrane packs.

Function

- The indicator, operating on the float principle, remains in a resting position as long as no dewatering medium flows.

- As long as the filter cake is compressible, the indicator remains in a floating state and visualizes the incomplete dewatering.

- At maximum deflection, the entire flow cross-section is cleared.

- In the event of a leak in a membrane plate, the indicator for this plate behaves contrary to the indications of the others, thus enabling the precise localization of a dewatering media loss.

Application

- Indication of the end of the dewatering process

- Localization and detection of defects and leaks

- Suitable for gaseous (e.g., air) or liquid dewatering media (e.g., water, oil)

JVK® Repress indicator for membrane chamber plates

The JVK® membrane chamber plate with integrated squeeze-out indicator is successfully in use worldwide.