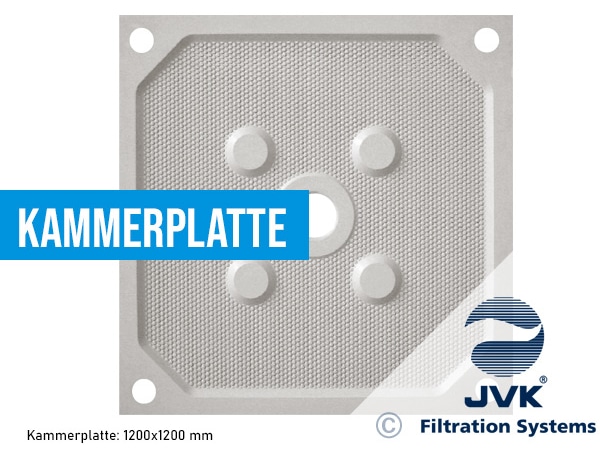

Chamber plate

JVK® chamber plates 300-2500 mm

Robust. Precisely fitting. Process reliability – for every industry.

JVK® manufactures chamber plates for filter presses in sizes from 300 to 2500 mm. The plates are designed for all industries – from mining and chemicals to ceramics, food and pharmaceuticals to environmental technology and recycling. Flow-optimized geometries, precise sealing zones and durable materials ensure short cycles, low residual moisture and clean filtrates.

Benefits at a Glance

- Wide range of sizes: 300-2500 mm, including special formats

- Service life & stability: low-wear materials, reinforced edges

- Clean operation: defined sealing zones, optional CGR seal

- High flow rates: large flow cross-sections, optimized drainage surfaces

- Compatible & retrofit-capable: perfect fit for common press types (e.g. Metso/SALA, Ishigaki) and special systems

Technical data & options

- Sheet body: PP or PVDF

- Cake thicknesses: project-specific (typically 15-50 mm, others on request)

- Inlet: Center or corner inlet, optional washing channels/cake washing

- Seal: classic or CGR (Caulked/Gasketed/Recessed)

- Thermal & process: optional TCC/TCM (temperature-controlled), squeeze-out indicator

- Cloths & changing: optimized filter cloths, quick change with SnapFit®

Applications

- Mining & Mineral Processing: Concentrates, Tailings

- Chemistry & fine chemistry: Suspensions with demanding media

- Ceramics & Pigments

- Food & Beverages

- Pharma & Biotech

- Environmental technology & sludge, recycling

Design & Service

We dimension the cake thickness, inlet, seal and cloth based on the medium, temperature, pH and target values (residual moisture, cycle time). Retrofit with test plate and fit test on request.

FAQs

What sizes does JVK® offer?

Chamber panels in 300-2500 mm, including special formats.

Can JVK® panels be retrofitted?

Yes, we supply custom-fit solutions for many types of presses and implement retrofit solutions.

What materials are available?

Plate body made of PP or PVDF; suitable filter cloths made of PP/PES/PA depending on the process.