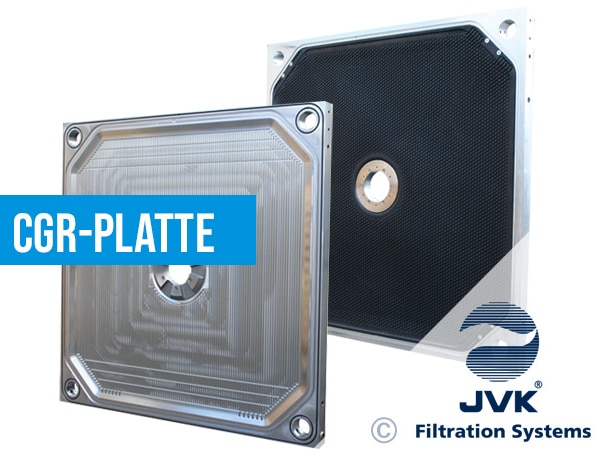

CGR Plate

JVK® CGR panels

Caulked – Gasketed – Recessed – the dense chamber plate

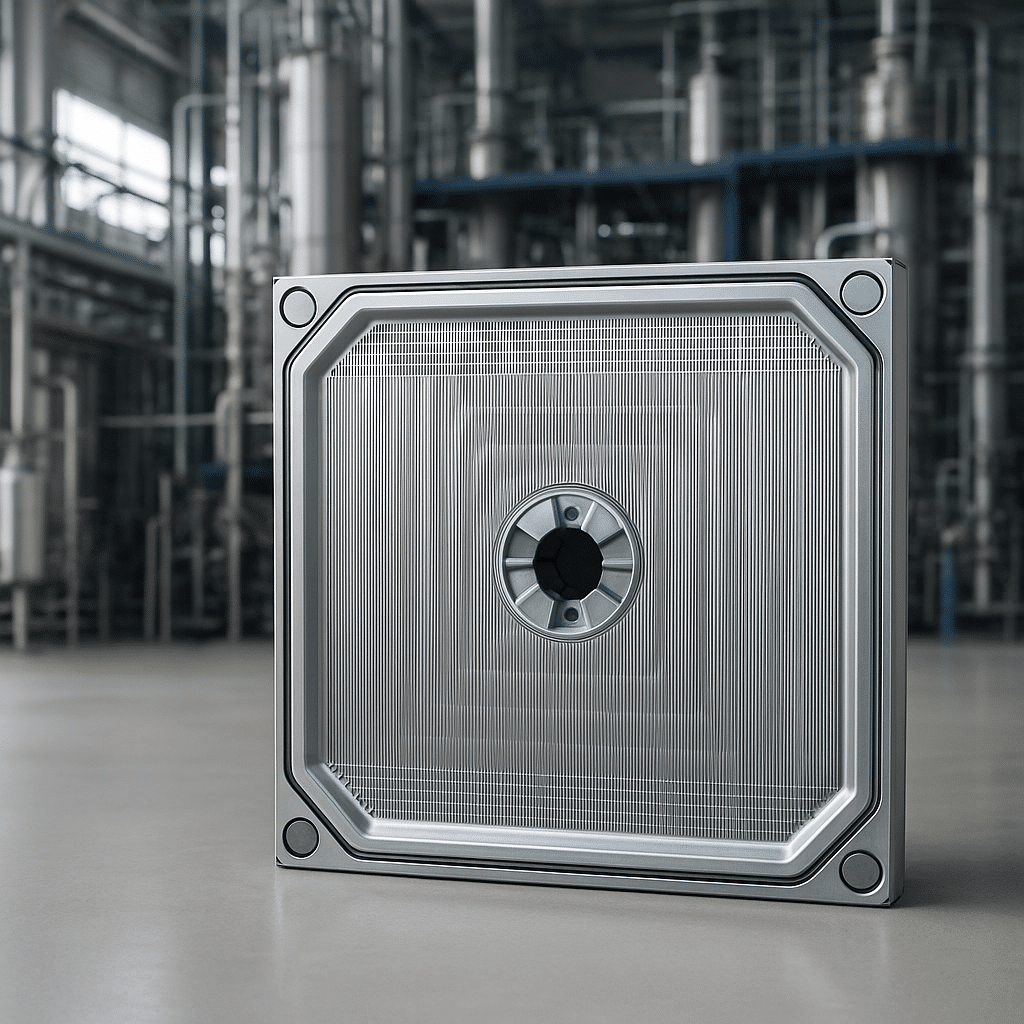

JVK® CGR plates are sealed chamber plates with a circumferential seal in a groove (“caulked/gasketed”) and recessed chamber (“recessed”). The result: drip-free edge sealing, clean filtrates and reduced cleaning effort – ideal for demanding media and high availability requirements.

Benefits at a Glance

- High tightness: defined sealing groove, suitable sealing profile (EPDM/NBR/FKM).

- Clean operation: less leakage, less contamination on the press.

- Short downtimes: low-wear seals, optionally replaceable.

- Stable process: reproducible contact pressure, uniform cake formation.

- Flexible & retrofit-capable: Designed for existing presses and sizes.

Technical design

- Plate body: PP or PVDF, flow-optimized channels.

- Seals: EPDM, NBR, FKM – suitable for medium, temperature, pH.

- Geometry: Recessed chamber (CGR), inlet center or corner.

- Options: Wash channels, cake washing, squeeze-out indicator; membrane version with CGR seal on request.

Performance with matching scarves

The tightness of a CGR panel is optimized with correctly assembled filter cloths (hole patterns, sealing zones, air permeability).

→ JVK® filter cloths

Quick cloth changes – tool-free and reproducible – are possible with:

→ JVK® SnapFit®

Applications

Mining (concentrates/tailings), chemicals & fine chemicals, ceramics, pigments, environmental technology – wherever residual moisture, cleanliness and process reliability count.

Design & Service

We match the cake thickness, sealing material, cloth selection and infeed concept to your medium and your target values (residual moisture, cycle time). Retrofit incl. test plate and fit test on request.

FAQs

What does CGR mean?

Caulked Gasketed Recessed: sealed chamber plate with seal in groove and lowered chamber for drip-free operation.

Can JVK® CGR panels be retrofitted?

Yes, we manufacture custom-fit presses for many presses (e.g. Metso/SALA, Ishigaki) and special sizes.

Which sealing materials does JVK® use?

EPDM, NBR or FKM – selected according to chemical resistance, temperature and pH.