The company

What makes JVK unique?

Perfect Filtration. Worldwide!

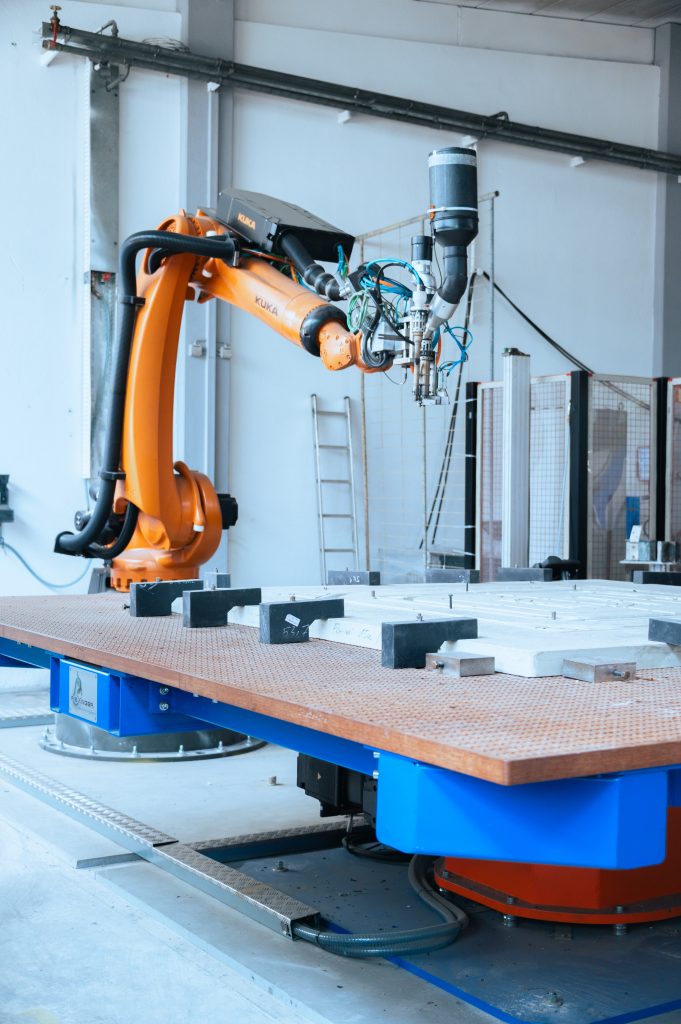

Technological

Expertise

We have experience in process and filtration technology since 1962 and have a deep understanding of a wide range of applications and industries.

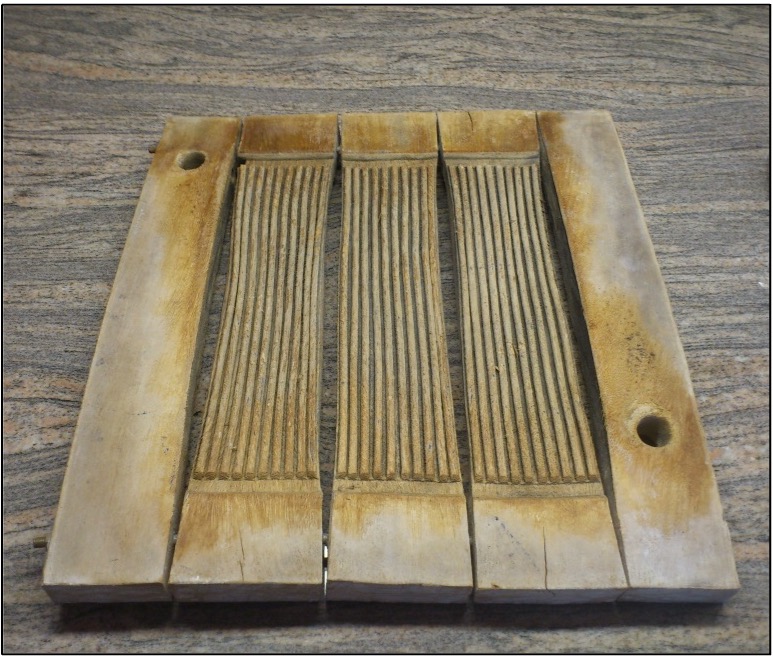

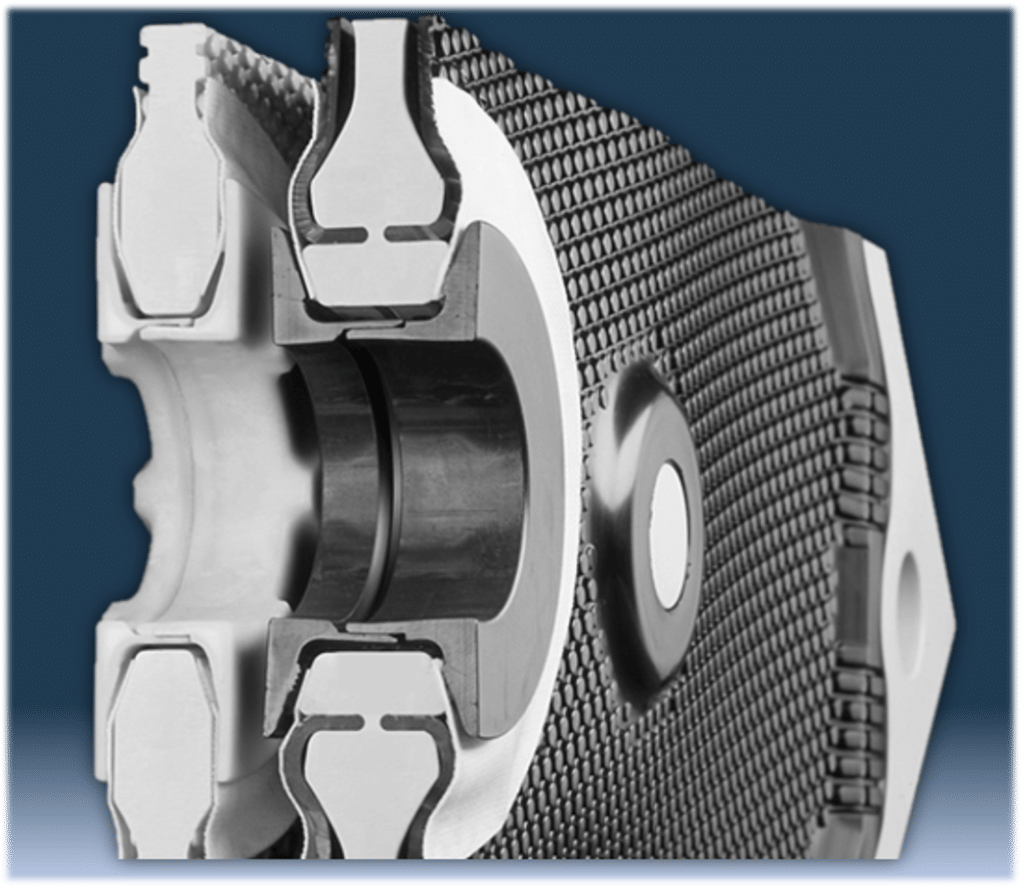

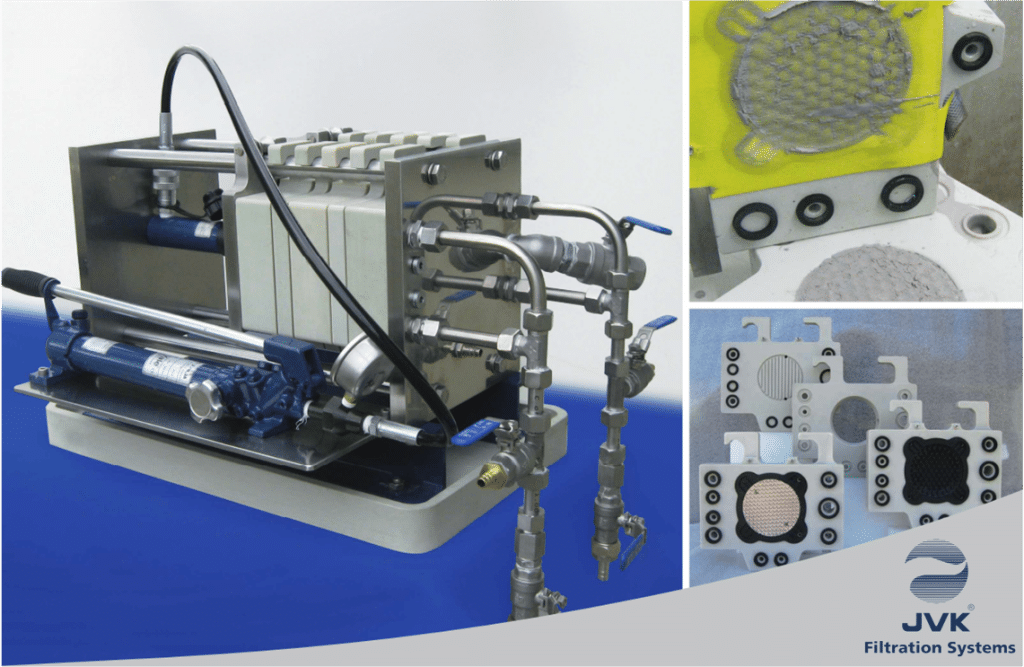

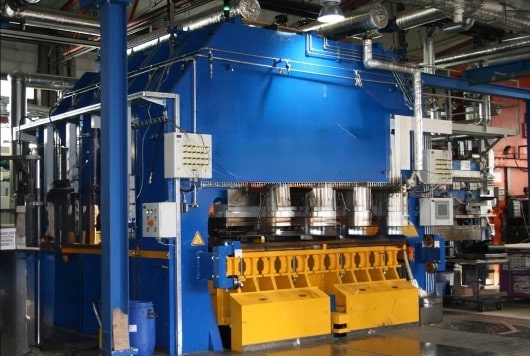

Our expertise ranges from the development of innovative filter elements made of high-quality thermoplastics and aluminum to the implementation of complex special solutions.

Highest

quality standards

JVK is a Bavarian family business in which cohesion and reliability characterize everyday life. Many colleagues have been on board for years – often decades. Their knowledge remains within the company and makes our solutions stable and comprehensible. The atmosphere is friendly, informal and respectful: people know each other, listen to each other and value each individual service. For customers, this means fixed contacts, short distances and quality that can be measured – Made in Germany, from Bavaria.

JVK – Technology with heart, quality with substance.

Customer-Centric

Solutions

Every filtration task is unique – and we design our solutions just as individually.

Thanks to flexible manufacturing, we can specifically address individual customer requirements and precisely adapt products to your processes.

Our experts offer comprehensive consultation – also directly on-site – and are ready with fast, practical solutions to resolve filtration problems and sustainably optimize processes.

JVK History & Innovations

JOH.JAC.VOWINCKEL was the first company worldwide to begin producing filter plates from polyolefins. Even today, filter plates and filter elements from that era are still in use.

Acquisition of production facilities and know-how of Joh. Jac. Vowinckel GmbH by JVK Filtration Systems GmbH

Acquisition of competitor HANSEN BTR. The membrane plate with interchangeable rubber membranes significantly complemented the JVK product range.

Expansion through the acquisition of production facilities for the manufacture of filter plates from a renowned filter press manufacturer.

In use worldwide –

since 1962

As a pioneer in the production of filter elements made of thermoplastic materials, JVK® is still one of the leading manufacturers of innovative filter elements made of thermoplastics and other high-quality materials. Our products are known and successfully used in numerous countries around the world – from Europe to Asia and Africa to North and South America.

We have been combining technical expertise with extensive experience in solid-liquid separation since 1962. In process and production engineering, we use state-of-the-art methods to manufacture filter elements of all kinds that meet the highest quality and performance requirements.

Thanks to our global network of partners and representatives, we are close to our customers – wherever reliable filtration is required.

JVK® - Creating quality together.

JVK® – technology with heart, quality that lasts.

Shape the future of filtration

with us

As a leading manufacturer of filter presses, we value collaborative partnerships, precise working methods, and a welcoming work environment. Our culture is characterized by collaborative teamwork, openness, and the enthusiasm to jointly develop the best solutions.

Career start at JVK (m/f/d)

Do you want to get started after your apprenticeship, studies or as a career changer? At JVK, you can expect a familiar atmosphere, reliable teams and technology “Made in Germany (Bavaria)”. We work on solutions for filtration, mold making and process engineering – and give you room to quickly take on responsibility.

What awaits you: structured induction & mentoring, real practice instead of boredom, appreciative interaction, development opportunities in production, design/mold making, laboratory & QA, logistics or administration.

Sounds good? Apply on your own initiative – we look forward to getting to know you!

Experienced professionals at JVK (m/f/d)

Do you want impact instead of routine? At JVK, you can contribute your experience in filtration, mold making and process engineering – in a familiar, reliable environment with long-term colleagues. We work pragmatically, appreciatively and as equals – Made in Germany (Bavaria).

Your opportunities: Responsibility from day one, short distances, modern equipment in manufacturing, laboratory & QA – plus further development in projects or specialist careers.

Apply now:

Students and interns (m/f/d)

Do you want real practice? At JVK, you will get to know filtration, mold making and process engineering where they happen: in the laboratory, in the pilot plant and in production. We offer mandatory and voluntary internships (8–26 weeks), working student positions (10–20 hours per week) as well as bachelor’s and master’s theses. There are clear tasks, a permanent contact person, mentoring, flexible times and a qualified certificate.

We help and support each other. It's like a second family.

Cüneyt Zafer - Produktionleiter

One team.

One vision.

Your chance.

Become part of the JVK team!

JVK Filtration Systems is the industry expert for filter solutions. Our filter elements for solid-liquid separation set standards in the plastics processing industry. With our expertise in materials science and constant innovation, we are the preferred supplier to capital equipment manufacturers worldwide. Our success is based on our commitment to excellence and our ability to meet customer requirements.

JVK Newsletter

Bleiben Sie auf dem Laufenden über Innovationen, Trends und praxisnahes Fachwissen in der Filtrationstechnik – mit unserem Newsletter.