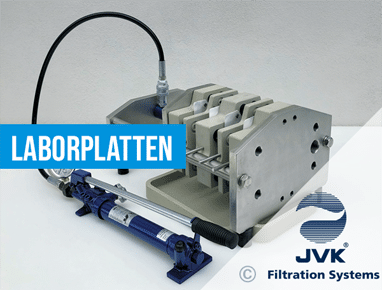

Laboratory Plates

Size: 150×150 to 500×500 mm

Application: in all industries

Features:

- Thermal cake drying

- Replaceable membrane

- Variable chamber depths via frame 15-50 mm

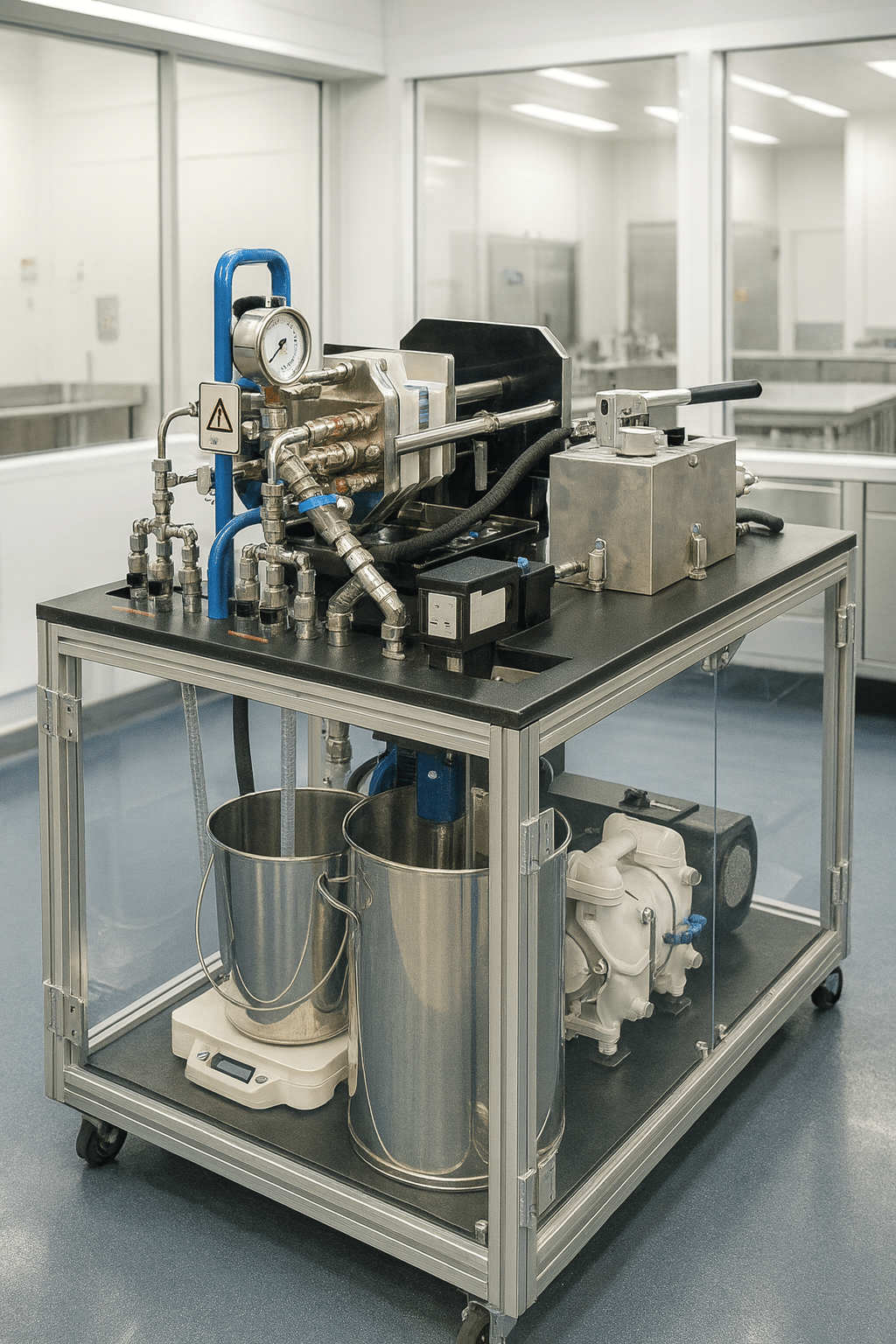

Laboratory filter press type JVK® LFP 150

Functional Principle

The laboratory filter press JVK® LFP 150 was developed to investigate new tasks in suspension and cake treatment and to improve existing applications. It is designed so that different methods of cake treatment can be presented and tested:

- Pressure filtration

- Repressing with membrane (max. 60 bar)

- Dry blowing with air

- Thermal cake drying

- Cake washing

The handy design allows the use directly on site at the customer’s premises. In conjunction with pneumatically controlled pumps, a compressed air network with 6 bar operating pressure is sufficient for operation. The appropriate chamber depth is set by selecting the correct filter frame thickness.

Complete Solution

The laboratory filter press JVK® LFP 150, type Gamma, can also be realized as a mobile version.

Available plate types

- JVK® MCP – Membrane combination plate

- JVK® MRP – Membrane chamber plate

- JVK® TCC – temperature-controllable chamber plate