JVK Filter Elements and especially JVK Membrane Plates have been proven successfully in many industrial filtration applications since 1962.

JVK has contributed significantly in many developments of the field of Solid-Liquid Separation with new ideas and designs.

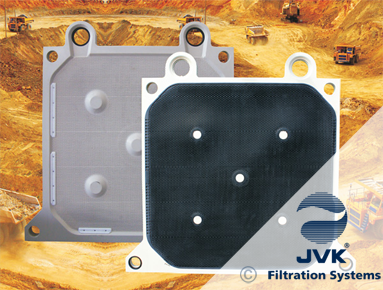

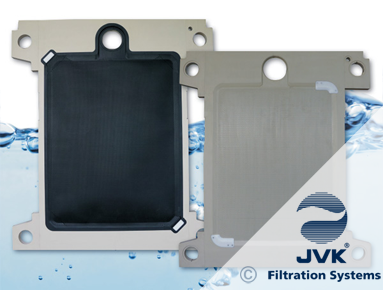

JVK is producing one piece moulded plates for filtration equipment in accordance with DIN standards or as special designs in polypropylene or other thermoplastic materials with the highest standard of ICM Technology.

JVK offers long-term experience in development, production and application of membrane plates. In 1964 the first trials with membrane plates had been completed in a chemical plant.

JVK started the production of membrane plates equipped with exchangeable elastomeric membranes in 1968. Plates with welded membrane are also available according to a new patent.

JVK membrane plates are successfully used worldwide due to the design, the high quality standard and the continuous product development.

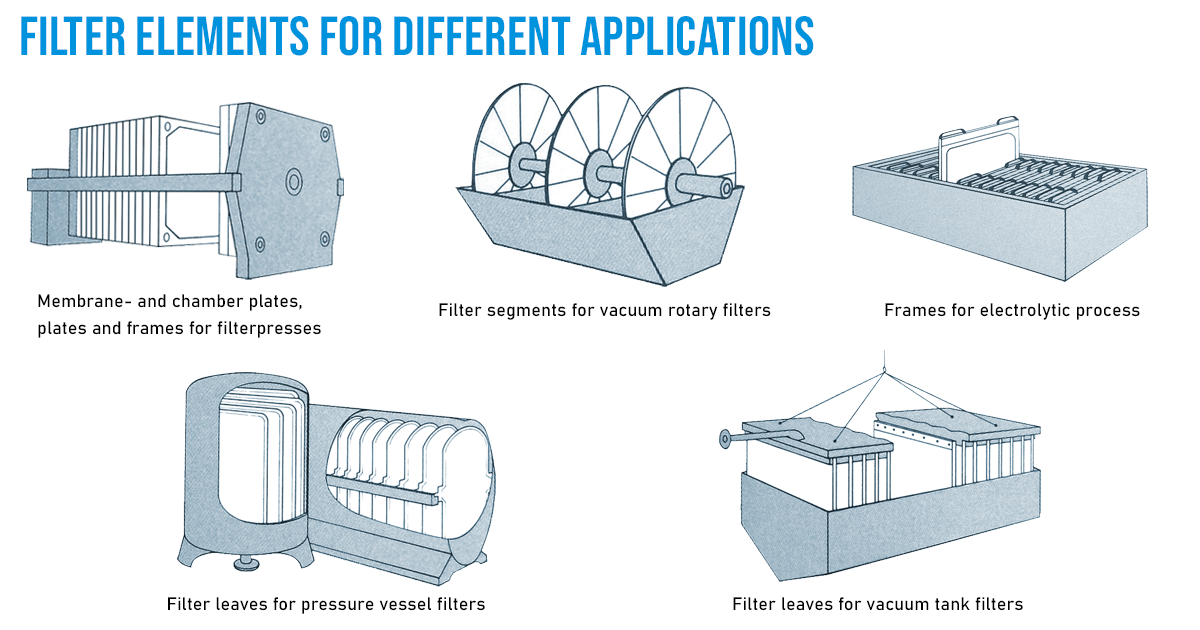

JVK FILTER ELEMENTS Overview >>

For Solid-Liquid-Separation worldwide successful in operation

Waste water treatment and

water purification for potable water

Dewatering and decontamination of industrial and

municipal waste water:

Waste liquids from dust scrubbers,

paper, leather and latex,

Grinding slurry of wood and stone,

Coal and ore suspensions from flotation processes

neutralization plants, oil refineries

Metal hydroxide sludges